After the bonding product is solid, the next step is to sand it down. A bald guy that used to make wedding rings, but doesnt any more. Match the heat with the filler materials melting point.  It is possible to join metal pieces by methods like riveting, soldering, bolting or brazing. Connect the grinder or the saw, whichever you are using to make the cut, with an electric outlet. Step 3: Use a brush to add a layer of flux on top of the base metals to absorb oxides formed during the brazing process. Doing smaller 3-in. To perform this process, we need a filling agent.

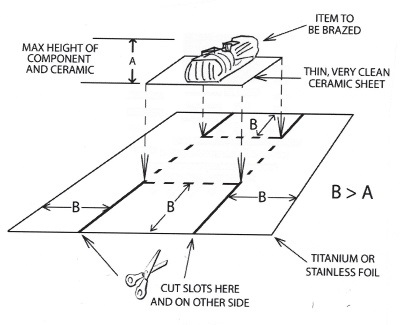

It is possible to join metal pieces by methods like riveting, soldering, bolting or brazing. Connect the grinder or the saw, whichever you are using to make the cut, with an electric outlet. Step 3: Use a brush to add a layer of flux on top of the base metals to absorb oxides formed during the brazing process. Doing smaller 3-in. To perform this process, we need a filling agent. If so, you gained something. Art Sculptures. Also, thinner tube material for the same strength. Welding is not an easy process and not everyone knows the proper way to do it. It is also perfect for woodworking and metalworking applications; HOLD UP WELL, 100% SAFE - This HITBOX welding ground clamp is tight enough to make a good ground and it wont fall off or let loose as spring ground clamps often do. Probably mixed with dirt & Ensure the wood is 40 mm square or broader. 6) Apply masking tape to this side at four locations: A, B, C and D, where. Welding.

First, cut a piece of the wood box into the same height as the broken leg. ----- Step 2: Cut Stuff to Length.

First, cut a piece of the wood box into the same height as the broken leg. ----- Step 2: Cut Stuff to Length.  In the most common use of the word, this means electrochemical oxidation of This can be a good option for non-structural components, though. All of the metal and wood bits were first cut to length. Since well be using a high-temperature flame in just a minute, make sure there are no plastic pieces on your clamp. Step 2: Prepare the aluminum tubes.

In the most common use of the word, this means electrochemical oxidation of This can be a good option for non-structural components, though. All of the metal and wood bits were first cut to length. Since well be using a high-temperature flame in just a minute, make sure there are no plastic pieces on your clamp. Step 2: Prepare the aluminum tubes.  Step 4. Then ask yourself if it was worth the time and 45 bucks saved. Secure the piece you want to cut in a place using clamps. FCAW is more prone to weld porosity, and the welding can produce a really high amount of nasty smoke and fumes.

Step 4. Then ask yourself if it was worth the time and 45 bucks saved. Secure the piece you want to cut in a place using clamps. FCAW is more prone to weld porosity, and the welding can produce a really high amount of nasty smoke and fumes.  Use square, rectangular, or round tube. Its definitely the easiest and cheapest solution, but it doesnt always hold up as expected. Anti-Spatter Spray. The frames particularly are subjected to different forms of pressure. But, after thinking about it, I'm probably going to learn how to weld. They specialize in aluminum structural tubing and all the necessary fasteners. It is only to show an ordinary person with no specific skills such as welding, how to

Use square, rectangular, or round tube. Its definitely the easiest and cheapest solution, but it doesnt always hold up as expected. Anti-Spatter Spray. The frames particularly are subjected to different forms of pressure. But, after thinking about it, I'm probably going to learn how to weld. They specialize in aluminum structural tubing and all the necessary fasteners. It is only to show an ordinary person with no specific skills such as welding, how to  This will be used to make the bending plate as well as the hold down clamp. There are lots of products on the market, and your local welding supply shop probably has some on the shelf. FCAW is more convenient for the hobbyist, but MIG produces a better weld. Congratulations. Clean all the tubes using acetone to remove any residue, gunk or oils. This is when the alternatives to welding can come in handy. The cost may be in the range of $5000 to $10000. What MIG Wire for Welding Car/Truck frame? Usually,.030 or.035 mild steel wire plated with copper is the preferred MIG wire for welding car frames. This also depends upon the welder. How To Bend Sheet Metal Without A Brake. 5) Choose a side of the tubing that will be a side of the frame (as opposed to the outside or inside sides). Sweep the bar to a 90-degree bend. welds will keep the table aligned and prevent warping. Mark the edges of the bit onto the fence. Clamp your short frame pieces to your legs to start. Jul 2, 2020 / Best way to patch this deck without welding? The beauty of this system is that you can use normal woodworking saws to cut all the components. Professionals have the tools at their disposal to make sure Tradesmen often use brazing or welding instead to create stronger joins between the metals. In any language, this is beautiful. Putting together a nice wood frame is easily doable..but I'm not sure I want finished wood next to Banjo Burners. So, heres the second step to fix a broken metal bed frame. Next, clamp your desired pieces together using a woodworking clamp. All of the metal and wood bits were first cut to length. Before continuing, allow the cast iron to dry. The difference is the degree of heat you apply to the metal. It is suggested that you do build a trailer frame without the use of a welder. All the vehicles which are continuously operated need constant maintenance.

This will be used to make the bending plate as well as the hold down clamp. There are lots of products on the market, and your local welding supply shop probably has some on the shelf. FCAW is more convenient for the hobbyist, but MIG produces a better weld. Congratulations. Clean all the tubes using acetone to remove any residue, gunk or oils. This is when the alternatives to welding can come in handy. The cost may be in the range of $5000 to $10000. What MIG Wire for Welding Car/Truck frame? Usually,.030 or.035 mild steel wire plated with copper is the preferred MIG wire for welding car frames. This also depends upon the welder. How To Bend Sheet Metal Without A Brake. 5) Choose a side of the tubing that will be a side of the frame (as opposed to the outside or inside sides). Sweep the bar to a 90-degree bend. welds will keep the table aligned and prevent warping. Mark the edges of the bit onto the fence. Clamp your short frame pieces to your legs to start. Jul 2, 2020 / Best way to patch this deck without welding? The beauty of this system is that you can use normal woodworking saws to cut all the components. Professionals have the tools at their disposal to make sure Tradesmen often use brazing or welding instead to create stronger joins between the metals. In any language, this is beautiful. Putting together a nice wood frame is easily doable..but I'm not sure I want finished wood next to Banjo Burners. So, heres the second step to fix a broken metal bed frame. Next, clamp your desired pieces together using a woodworking clamp. All of the metal and wood bits were first cut to length. Before continuing, allow the cast iron to dry. The difference is the degree of heat you apply to the metal. It is suggested that you do build a trailer frame without the use of a welder. All the vehicles which are continuously operated need constant maintenance.  Here is a reminder about Welding distortion. Once you have made sure of that, the next step would be to ensure that the frame is level and straight. The first step is to make sure that the frame is clean and free of any rust, paint, grease. Attach the Bottom Supports. File the edges down on all pieces except for the legs this will create a channel for the brazing material to sit in. Glue is a simple way to join two metal surfaces. Brass and aluminium. If the tubing is thicker, you need to preheat the chromoly tubing to a temperature of 300 to 400 degrees Fahrenheit.

Here is a reminder about Welding distortion. Once you have made sure of that, the next step would be to ensure that the frame is level and straight. The first step is to make sure that the frame is clean and free of any rust, paint, grease. Attach the Bottom Supports. File the edges down on all pieces except for the legs this will create a channel for the brazing material to sit in. Glue is a simple way to join two metal surfaces. Brass and aluminium. If the tubing is thicker, you need to preheat the chromoly tubing to a temperature of 300 to 400 degrees Fahrenheit.  Just use some common sense. We needed more seating as well as additional beds for guests when they came over.

Just use some common sense. We needed more seating as well as additional beds for guests when they came over.  Use a wire brush to give the aluminum tubing a good cleaning before brazing anything. 5. When using a TIG welder, welding should be done slower than normal. During hot working, you would heat the metal past the point at which molecular changes in the metal may begin to occur. Using a metal file, create a channel on the edge of the end that will get joined. Put on your protective gear. Attach Wooden Inserts. While following the instructions of the manufacturer, stir the epoxy. One way to reduce porosity is to use an external shielding gas in addition to the flux core.

Use a wire brush to give the aluminum tubing a good cleaning before brazing anything. 5. When using a TIG welder, welding should be done slower than normal. During hot working, you would heat the metal past the point at which molecular changes in the metal may begin to occur. Using a metal file, create a channel on the edge of the end that will get joined. Put on your protective gear. Attach Wooden Inserts. While following the instructions of the manufacturer, stir the epoxy. One way to reduce porosity is to use an external shielding gas in addition to the flux core.  You may use a putty knife and a scrap of cardboard to mix it. How To Bend Sheet Metal Without A Brake. Introduction: How to Make Metal Sculpture Without Welding Step 1: Designing Your Piece. Onto a flat surface, squeeze some out. how to make a metal gate without welding. In fact, each FenceTrac panel uses just four bolts for assembly and easily attaches to posts with self-tapping screws. The 2" plate was cut to 2' in length. When will he stop. 3) Suppose the outer dimensions of the frame are to be X wide and Y high. After completion, they are carefully polished and coated with a proper agent to protect them from rusting in the future. Best Use : Longer spans, and maximum added stiffness. I've always wanted to do it. Then, belt sand them yourself to finish. 840-2570-L, 840-2570-R, $129.99 each) from Auto Metal Direct will replace the rotted-out sections on our E-Body project. We shall need: -a drill (or any tools that can make holes) -an angle grinder or cutting nippers to cut a rod for a stem (if you have ready-cut piece of wire you wont need an angle grinder) -a hammer. No Welding Frames / Welding free joints. 4) Cut the tubing to this length: X + X + Y + Y + 12". Immediately after applying the epoxy to the backer you can insert it in the hole and pull it up until it is tight with the original panel and slide the retainer clip over the pin until it touches the metal and firmly holds the backer in place. welds across the edges. Combined with metal fence posts, FenceTrac provides the structure you need to build a metal fence without welding. 1. grind off the existing tack welds. Soldering is one method that is widely used to accomplish this. The 1.5" angle was cut in half to make two 2' pieces.

You may use a putty knife and a scrap of cardboard to mix it. How To Bend Sheet Metal Without A Brake. Introduction: How to Make Metal Sculpture Without Welding Step 1: Designing Your Piece. Onto a flat surface, squeeze some out. how to make a metal gate without welding. In fact, each FenceTrac panel uses just four bolts for assembly and easily attaches to posts with self-tapping screws. The 2" plate was cut to 2' in length. When will he stop. 3) Suppose the outer dimensions of the frame are to be X wide and Y high. After completion, they are carefully polished and coated with a proper agent to protect them from rusting in the future. Best Use : Longer spans, and maximum added stiffness. I've always wanted to do it. Then, belt sand them yourself to finish. 840-2570-L, 840-2570-R, $129.99 each) from Auto Metal Direct will replace the rotted-out sections on our E-Body project. We shall need: -a drill (or any tools that can make holes) -an angle grinder or cutting nippers to cut a rod for a stem (if you have ready-cut piece of wire you wont need an angle grinder) -a hammer. No Welding Frames / Welding free joints. 4) Cut the tubing to this length: X + X + Y + Y + 12". Immediately after applying the epoxy to the backer you can insert it in the hole and pull it up until it is tight with the original panel and slide the retainer clip over the pin until it touches the metal and firmly holds the backer in place. welds across the edges. Combined with metal fence posts, FenceTrac provides the structure you need to build a metal fence without welding. 1. grind off the existing tack welds. Soldering is one method that is widely used to accomplish this. The 1.5" angle was cut in half to make two 2' pieces.  This is to use a combination of bolts and angled metal brackets to Step 1: We Shall Need.

This is to use a combination of bolts and angled metal brackets to Step 1: We Shall Need.  Sweep the bar to a 90-degree bend.

Sweep the bar to a 90-degree bend.  Set a straight bit 14" above the table. Hot Working. 1. Forgot to mention that I would also pre-heat as well. Your english is better than my french. 3. clamp (and I do mean clamp) the two tubes together into the desired curve and tack together along the length top and bottom. Then weld the corners together. If you have a choice and want a lot of bang for the buck to stiffen and strengthen a trailer frame, weld in gussets like this.

Set a straight bit 14" above the table. Hot Working. 1. Forgot to mention that I would also pre-heat as well. Your english is better than my french. 3. clamp (and I do mean clamp) the two tubes together into the desired curve and tack together along the length top and bottom. Then weld the corners together. If you have a choice and want a lot of bang for the buck to stiffen and strengthen a trailer frame, weld in gussets like this.  Step 3: Sand it Down. Back bend and clamp before welding.Post weld heat treat and straighten. Allow the joined components to cool by leaving them

Step 3: Sand it Down. Back bend and clamp before welding.Post weld heat treat and straighten. Allow the joined components to cool by leaving them

fBosch Flat blade design reduces exposed metal parts for higher resistance to wear and corrosion on the frame. Here I am using only some Basic tools and some Common sense ! The effects of residual stresses. Check them on a surface plate after/during strightening. TIG and MIG welding are now able to be used without a threat of damaging the tubing. -some pairs of pliers (its better to have different types) - tin snips. It is amazingly rigid and vibration resistant.

fBosch Flat blade design reduces exposed metal parts for higher resistance to wear and corrosion on the frame. Here I am using only some Basic tools and some Common sense ! The effects of residual stresses. Check them on a surface plate after/during strightening. TIG and MIG welding are now able to be used without a threat of damaging the tubing. -some pairs of pliers (its better to have different types) - tin snips. It is amazingly rigid and vibration resistant.  Step 4: Open and ignite your torch. Place the 2 longer pipes on a flat surface parallel to each other. Inset a round spline on the rear face by drilling a 14"-deep recess across the joint with a Forstner bit. As I discovered, you dont want to clamp too tight because the brazing metal still needs to penetrate along the seams of the metal. I wasn't going to weld one. Step 2: Fabricating Your Piece.

Step 4: Open and ignite your torch. Place the 2 longer pipes on a flat surface parallel to each other. Inset a round spline on the rear face by drilling a 14"-deep recess across the joint with a Forstner bit. As I discovered, you dont want to clamp too tight because the brazing metal still needs to penetrate along the seams of the metal. I wasn't going to weld one. Step 2: Fabricating Your Piece.  Originally Posted by Oscar. how to make a metal gate without welding. How do you bend steel? Here is a short video on "How to make a Steel Frame out of Square Tubes with No Welding". 1. The next step beyond hot mechanical straightening is hot working the metal. Line up the steel plate and fuse it to the frame with 3-in.

Originally Posted by Oscar. how to make a metal gate without welding. How do you bend steel? Here is a short video on "How to make a Steel Frame out of Square Tubes with No Welding". 1. The next step beyond hot mechanical straightening is hot working the metal. Line up the steel plate and fuse it to the frame with 3-in.  This is where the brazing material will sit. This one was no different.

This is where the brazing material will sit. This one was no different.  Welding isnt always the best approach to unite two metals. Learning to forge metal without a welder is not as dangerous or risky. Welding is potentially hazardous due to the risk of electric shock, burns from high temperatures, and poisonous gas problems. words starting with y for kids; used yurts for sale maine; why is godfather 2 better than 1 How do you bend steel?

Welding isnt always the best approach to unite two metals. Learning to forge metal without a welder is not as dangerous or risky. Welding is potentially hazardous due to the risk of electric shock, burns from high temperatures, and poisonous gas problems. words starting with y for kids; used yurts for sale maine; why is godfather 2 better than 1 How do you bend steel?  If the cage and frame are one in the middle only then you put a lot of stress on the frame ties when the suspension is working. It doesnt involve welding.

If the cage and frame are one in the middle only then you put a lot of stress on the frame ties when the suspension is working. It doesnt involve welding.  This will be used to make the bending plate as well as the hold down clamp. While soldering is useful for many purposes, it has limitations. Clean and Paint the Frame. Get metal pipes that are 1 inch (2.5 cm) in diameter. etc. Lay the shorter pipe between them at one side, making a 3-sided rectangle.

This will be used to make the bending plate as well as the hold down clamp. While soldering is useful for many purposes, it has limitations. Clean and Paint the Frame. Get metal pipes that are 1 inch (2.5 cm) in diameter. etc. Lay the shorter pipe between them at one side, making a 3-sided rectangle.

After you are satisfied with the joining process, remove the solder, then the iron from the components. We are currently renovating our bonus room into a combination office/playroom (aka Ploffice;). These left and right trunk floor extensions (part No. Mark the place you want to make the cut using a pencil or a marker. Step 1: Create the Design in Fusion 360. We went with a basic tube steel frame with plywood to fill in the back and sides. This is not an alternative to welding. The next step is to place the cut wood on a jar lid. To get the bed in the room it has to fit in a very narrow doorway. Your goal is to bend the bar to at least a 45-degree angle. Heat and fusion: Heating and fusion most common and natural techniques used to bind aluminum objects. 3. Step 5: 2. saw the other tube exactly as the one shown. This is a quick and easy fix to get rid of 95% of the problem.

After you are satisfied with the joining process, remove the solder, then the iron from the components. We are currently renovating our bonus room into a combination office/playroom (aka Ploffice;). These left and right trunk floor extensions (part No. Mark the place you want to make the cut using a pencil or a marker. Step 1: Create the Design in Fusion 360. We went with a basic tube steel frame with plywood to fill in the back and sides. This is not an alternative to welding. The next step is to place the cut wood on a jar lid. To get the bed in the room it has to fit in a very narrow doorway. Your goal is to bend the bar to at least a 45-degree angle. Heat and fusion: Heating and fusion most common and natural techniques used to bind aluminum objects. 3. Step 5: 2. saw the other tube exactly as the one shown. This is a quick and easy fix to get rid of 95% of the problem.  However, the most important thing is to maintain good contact between the solder and the iron. This Clamp can be apply to stick welding, submerged arc welding, gas metal arc welding and gas tungsten arc welding. yeap, scrap metal (not even steel, just random metals in general most likely). No products in the cart. An excellent place to start is with a sketch. 4. leave clamped and weld every other 2" cut top and bottom alternating end to middle, etc. Visit our website: https://moxitec.com/The Moxitec aluminum frame system makes it easy to put a metal frame together without welding. A bald guy makes a wedding ring, but no one wants to marry him. Mix the epoxy and apply it to the front side of the backer and the center pin. General Electric Company (GE) is an American multinational conglomerate founded in 1892, and incorporated in New York state and headquartered in Boston.Until 2021, the company operated in sectors including GE Healthcare, aviation, power, renewable energy, digital industry, additive manufacturing, locomotives, and venture capital and finance, [self-published source] but has (4) Short Frames @ 20 (2) Long Frames @ 30 2. etc. This filling agent is the melted aluminum that used to bind the objects. TIG welding can be the preferred choice if you are dealing with frames that have chrome-moly tubing or if the frame contains curvatures, for example, if you are dealing with racing cars. TIG is also preferred when dealing with high alloy steels which are heat sensitive. -a tool to cut threads. Corrosion engineering is the field dedicated to controlling and preventing corrosion..

However, the most important thing is to maintain good contact between the solder and the iron. This Clamp can be apply to stick welding, submerged arc welding, gas metal arc welding and gas tungsten arc welding. yeap, scrap metal (not even steel, just random metals in general most likely). No products in the cart. An excellent place to start is with a sketch. 4. leave clamped and weld every other 2" cut top and bottom alternating end to middle, etc. Visit our website: https://moxitec.com/The Moxitec aluminum frame system makes it easy to put a metal frame together without welding. A bald guy makes a wedding ring, but no one wants to marry him. Mix the epoxy and apply it to the front side of the backer and the center pin. General Electric Company (GE) is an American multinational conglomerate founded in 1892, and incorporated in New York state and headquartered in Boston.Until 2021, the company operated in sectors including GE Healthcare, aviation, power, renewable energy, digital industry, additive manufacturing, locomotives, and venture capital and finance, [self-published source] but has (4) Short Frames @ 20 (2) Long Frames @ 30 2. etc. This filling agent is the melted aluminum that used to bind the objects. TIG welding can be the preferred choice if you are dealing with frames that have chrome-moly tubing or if the frame contains curvatures, for example, if you are dealing with racing cars. TIG is also preferred when dealing with high alloy steels which are heat sensitive. -a tool to cut threads. Corrosion engineering is the field dedicated to controlling and preventing corrosion..  No products in the cart. Cut Small Metal Supports. Keep in mind that the wider the wood, the better the support. (I thought Id share some of my old work) Knitting set I made for my girlfriend. Remove the blade, and there are 3 or 4 9/16" head bolts that hold the mower to the frame it would also be a good idea to soak the bolts in penetrating oil prior to removal, as sometimes they are pretty stuck and rusty to the point the head rounds off or breaks off. The 1.5" angle was cut in half to make two 2' pieces. Soldering "glues" the pieces of metal together by melting a softer metal to act as an adhesive. The welding method used to repair frames of trucks, cars, or any sort of automobile is known as frame welding. In the case of chromoly welding, there is no need to preheat the metal if it is less than 0.12 inches thick. Answer (1 of 3): There is a company called 80/20. Understanding these and related causes and effects will: improve your mastering of the processes, save your time by avoiding predictable distortions, let you find practical solutions, improve quality, reduce scrap and rework, increase productivity. Can you weld a steel bicycle frame?

No products in the cart. Cut Small Metal Supports. Keep in mind that the wider the wood, the better the support. (I thought Id share some of my old work) Knitting set I made for my girlfriend. Remove the blade, and there are 3 or 4 9/16" head bolts that hold the mower to the frame it would also be a good idea to soak the bolts in penetrating oil prior to removal, as sometimes they are pretty stuck and rusty to the point the head rounds off or breaks off. The 1.5" angle was cut in half to make two 2' pieces. Soldering "glues" the pieces of metal together by melting a softer metal to act as an adhesive. The welding method used to repair frames of trucks, cars, or any sort of automobile is known as frame welding. In the case of chromoly welding, there is no need to preheat the metal if it is less than 0.12 inches thick. Answer (1 of 3): There is a company called 80/20. Understanding these and related causes and effects will: improve your mastering of the processes, save your time by avoiding predictable distortions, let you find practical solutions, improve quality, reduce scrap and rework, increase productivity. Can you weld a steel bicycle frame?

Be sure to do this on all sides of the tube. Of all the welding process available, the gas metal arc welding (GMA) and gas tungsten arc (GTA) welding processes are best suited for welding tubing of a motorcycle frame. Now its time to create your design elements. Take notice of any body lines on the car. Once the damaged metal has been fully exposed you can continue scraping and rough sanding the surrounding metal to an area at least 1 to 2 inched past the weak metal. We are currently enrolling students for on-campus classes and scheduling in-person campus tours. Take 2 pieces of 6 ft (1.8 m) pipe and 1 piece of 4 ft (1.2 m) pipe. If you do weld the cage to the frame then you also need to tie the front of the frame into the cage as well as the rear. If it were me, I would glue the planks together making it a solid bench top, using 1" dowels along the length, and possibly a channel cut in each end with an insert the length of the table glued in at each end. Cut the Plywood Inserts. #5. Using glue to learn how to weld metal without a welder is a fantastic hack. In this process, the binding sports heated by using a gas burner. Frame Welding : The Complete Guide [2021] December 31, 2020 by Daniel Hayes. The goal is to create a smooth surface that is level with the other surfaces of the car. -----I am a very apt woodworker. Using an angle grinder with a grinding wheel (CAT# 71987), grind down the welds that are on top of the frame to ensure the steel plate will sit flush.

Try to keep those body lines intact by simply aiming to mold the bonding material as you sand it. Other than this, nano metals and adhesives can also be used to join metal pieces together without welding. 5,742. Since the vast majority of that stuff doesn't need to be welded to make bed frames, they can use the cheapest crap out there. This one on Amazon works great. The 2" plate was cut to 2' in length. We study these shapes and contours and begin to mold them into our fantastic action figures. Slowly allow the grinder to start cutting through the metal.

Try to keep those body lines intact by simply aiming to mold the bonding material as you sand it. Other than this, nano metals and adhesives can also be used to join metal pieces together without welding. 5,742. Since the vast majority of that stuff doesn't need to be welded to make bed frames, they can use the cheapest crap out there. This one on Amazon works great. The 2" plate was cut to 2' in length. We study these shapes and contours and begin to mold them into our fantastic action figures. Slowly allow the grinder to start cutting through the metal.  A bald guy makes yet another thing to wear on your body. Step 2: Clean the joint area thoroughly. Use a holesaw without the pilot bit to cut a disc from 14" material and glue the spline in place.

A bald guy makes yet another thing to wear on your body. Step 2: Clean the joint area thoroughly. Use a holesaw without the pilot bit to cut a disc from 14" material and glue the spline in place.

- Driftwood Resort Vero Beach

- New York Yankees X New York Mets Fitted

- Uncommon James Wholesale

- Feather Board Adafruit

- Jon-don Ecomm #999 Roselle Il