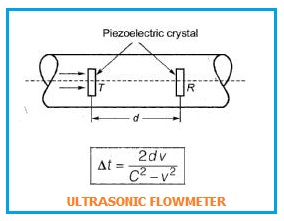

c = speed of wave in process fluid. Your email address will not be published. Doppler open channel measurement can use one transducer to measure velocity, level and fluid conductivity. Here we discuss the pros and cons of ultrasonic flowmeters. Transit-time ultrasonic flow meters are usually considerably more accurate than Doppler measurement.

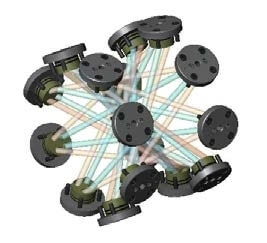

Advanced technologies of digital signal processing have made it possible to attach digital coding to the beamed sound waves. This website uses cookies to improve your experience while you navigate through the website. Most ultrasonic manufactures use low frequency sound pulses to measure the transit time there by severely limits their accuracy when bubbles/particles reach between 1-2% concentrations. The transducers are mounted, one opposite to another with an elevation which forms an upstream and downstream. The ideal tool for potable water applications, clamp-on ultrasonic flow meters can also be used in wastewater treatment and collection applications. Doppler flow meters can measure dirty liquid and transit-time ultrasonic flow meter main measure clean liquid. Performance Characteristics of Measuring Instruments. The electrodes sense and measure the voltage created as the liquid passes through the tube. High accuracy and stable performance can help to reduce your energy cost. Where V is the flow velocity to be measured, P is the ultrasonic path length, and is the acute angle between the ultrasonic path and the axis of the flow cell or pipe section. Our ultrasonic flow meters provide advanced and precision energy measurement and widely used for water energy monitor in HVAC management.

Advanced technologies of digital signal processing have made it possible to attach digital coding to the beamed sound waves. This website uses cookies to improve your experience while you navigate through the website. Most ultrasonic manufactures use low frequency sound pulses to measure the transit time there by severely limits their accuracy when bubbles/particles reach between 1-2% concentrations. The transducers are mounted, one opposite to another with an elevation which forms an upstream and downstream. The ideal tool for potable water applications, clamp-on ultrasonic flow meters can also be used in wastewater treatment and collection applications. Doppler flow meters can measure dirty liquid and transit-time ultrasonic flow meter main measure clean liquid. Performance Characteristics of Measuring Instruments. The electrodes sense and measure the voltage created as the liquid passes through the tube. High accuracy and stable performance can help to reduce your energy cost. Where V is the flow velocity to be measured, P is the ultrasonic path length, and is the acute angle between the ultrasonic path and the axis of the flow cell or pipe section. Our ultrasonic flow meters provide advanced and precision energy measurement and widely used for water energy monitor in HVAC management.  3.No Risk of Leakage Device will not obstruct flow or contaminate processes, Lack of moving parts means less maintenance, Zero pressure drop (Magnetic flow meters also provide no pressure drop if you are installing a meter the same size as the line size), Operates on pipe diameters from 1/2 to 200 (may require 2 or 3 different sets of transducer depending on pipe size and range transducers cover), Insensitive to changes in temperature, viscosity, density or pressure (Temperature will effect the transit time sensor selection requiring high temp sensors above 250F. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Susan Bender started selling to the natural gas industry in 1980. The ultrasonic gas flow meter is a velocity-type flow meter, a classification of meters that includes turbine meters and vortex meters. Less time in the direction of flow and more time against the flow. It is perfect when an application cannot be shut down or a pipe cannot be cut during installation. There are multiple industrial applications that call for the accurate flow measurement. # Ultrasonic flowmeters are no moving parts, need not worry about its wear and tear issues.

3.No Risk of Leakage Device will not obstruct flow or contaminate processes, Lack of moving parts means less maintenance, Zero pressure drop (Magnetic flow meters also provide no pressure drop if you are installing a meter the same size as the line size), Operates on pipe diameters from 1/2 to 200 (may require 2 or 3 different sets of transducer depending on pipe size and range transducers cover), Insensitive to changes in temperature, viscosity, density or pressure (Temperature will effect the transit time sensor selection requiring high temp sensors above 250F. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Susan Bender started selling to the natural gas industry in 1980. The ultrasonic gas flow meter is a velocity-type flow meter, a classification of meters that includes turbine meters and vortex meters. Less time in the direction of flow and more time against the flow. It is perfect when an application cannot be shut down or a pipe cannot be cut during installation. There are multiple industrial applications that call for the accurate flow measurement. # Ultrasonic flowmeters are no moving parts, need not worry about its wear and tear issues.  Have questions about our Ultrasonic Flow Meters? # Flow of both gases and liquids can be measured. Together with known pipe cross-section, the actual flow volume can be calculated. Users should do a right selection as the actual situation. With a clamp-on system, the sensors are fastened directly on to the outside of the pipeline. 6 Styles of Natural Gas Meters (Including Residential), Diaphragm Meter by Itron, Honeywell Elster Turbine Flowmeter, Measurement and Control of Natural Gas, Rotary Gas Meter, Slam Shut Valves, Regulators, and OPSO Regulator. However, users often dont know if they have excess bubbles or particles in their flow stream and often times user higher scan technologies with higher accuracies. This is the parameter being used by ultrasonic flowmeters to calculate the liquid flow rate.

Have questions about our Ultrasonic Flow Meters? # Flow of both gases and liquids can be measured. Together with known pipe cross-section, the actual flow volume can be calculated. Users should do a right selection as the actual situation. With a clamp-on system, the sensors are fastened directly on to the outside of the pipeline. 6 Styles of Natural Gas Meters (Including Residential), Diaphragm Meter by Itron, Honeywell Elster Turbine Flowmeter, Measurement and Control of Natural Gas, Rotary Gas Meter, Slam Shut Valves, Regulators, and OPSO Regulator. However, users often dont know if they have excess bubbles or particles in their flow stream and often times user higher scan technologies with higher accuracies. This is the parameter being used by ultrasonic flowmeters to calculate the liquid flow rate.  Doppler ultrasonic flowmeters are based on the Doppler-shift or the phenomenon in which the wavelength of an approaching sound source is shorter than the wavelength of that same source as it is moving away. Titanium transducers are not affected by erosion from condensate droplets and will not fail due to thermal expansion cycles. Ingress Protection (IP) and its NEMA equivalent ratings. Similar to many of the devices we examined in Not All Flow Meters Are Created Equal! Read more about the different types ofUltrasonic Flow meters: Clamp On Ultrasonic Flow MetersOpen Channel Flow MeterPortable Ultrasonic Flow MetersUltrasonic BTU Meters. An insiders guide to maintaining electrical enclosure temperatures and protecting heat-sensitive equipment. ultrasonic flowmeter. All rights reserved. The AlsonicDSP product line are used in both fixed and portable application as well as more complicated Area Velocity open channel techniques for sewers, small channels and rivers. The measured difference in the wavelengths (transmitted verses reflected) is proportional to the process velocity. Lets talk about water applications, for example. Every meter technology will have its advantages and disadvantages, but its the nuances of your system and what is flowing through it that should garner the most attention. It is mandatory to procure user consent prior to running these cookies on your website. The difference between these two amounts of time is directly proportional to the mean velocity of the liquid. a. Cant measure cement/concrete pipe or pipe with such material lining. Heating could take the form of warming a house or building to being a part of a large district heating system in which steam consumption is a significant concern due to billing and energy rebates. They dont cause the pressure to drop, and they can be used for bidirectional measurements.This method is different than other flow meters. This website uses cookies to improve your experience. Great product knowledge, prompt response and we don't have issues getting our products in a timely manner we can always count on Linc Energy Systems' reliable service. Ability to use multi-path techniques for flow profiling in large pipes or open channel applications. 15. Considerable costs are involved in maintaining, retesting and recalibrating other traditional flow technologies.

Doppler ultrasonic flowmeters are based on the Doppler-shift or the phenomenon in which the wavelength of an approaching sound source is shorter than the wavelength of that same source as it is moving away. Titanium transducers are not affected by erosion from condensate droplets and will not fail due to thermal expansion cycles. Ingress Protection (IP) and its NEMA equivalent ratings. Similar to many of the devices we examined in Not All Flow Meters Are Created Equal! Read more about the different types ofUltrasonic Flow meters: Clamp On Ultrasonic Flow MetersOpen Channel Flow MeterPortable Ultrasonic Flow MetersUltrasonic BTU Meters. An insiders guide to maintaining electrical enclosure temperatures and protecting heat-sensitive equipment. ultrasonic flowmeter. All rights reserved. The AlsonicDSP product line are used in both fixed and portable application as well as more complicated Area Velocity open channel techniques for sewers, small channels and rivers. The measured difference in the wavelengths (transmitted verses reflected) is proportional to the process velocity. Lets talk about water applications, for example. Every meter technology will have its advantages and disadvantages, but its the nuances of your system and what is flowing through it that should garner the most attention. It is mandatory to procure user consent prior to running these cookies on your website. The difference between these two amounts of time is directly proportional to the mean velocity of the liquid. a. Cant measure cement/concrete pipe or pipe with such material lining. Heating could take the form of warming a house or building to being a part of a large district heating system in which steam consumption is a significant concern due to billing and energy rebates. They dont cause the pressure to drop, and they can be used for bidirectional measurements.This method is different than other flow meters. This website uses cookies to improve your experience. Great product knowledge, prompt response and we don't have issues getting our products in a timely manner we can always count on Linc Energy Systems' reliable service. Ability to use multi-path techniques for flow profiling in large pipes or open channel applications. 15. Considerable costs are involved in maintaining, retesting and recalibrating other traditional flow technologies.  12. Meanwhile, the flow accuracy will degrade as using of moving parts.As its using, the moving parts will become bad and users have to replace a new flow measurement device. But opting out of some of these cookies may have an effect on your browsing experience. Conversely, the piezoelectric crystal creates a voltage when the ultrasonic signals touch the sensor. Smartmeasurement is the only manufacturer that uses both low frequency transit-time technologies and high frequency technologies as well as Doppler techniques. Meanwhile, even though it requires maintenance, the flow wont be stopped and production can continue. Lets review their pros and cons. SmartMeasurement s AlsonicDSP family of ultrasonic flow meters that use Digital Signal Processing techniques and their patented fine time measurement technologies that involve sound waves to be beamed at picoseconds to ensure accurate measurements of liquids that contain solids or gas bubbles.

12. Meanwhile, the flow accuracy will degrade as using of moving parts.As its using, the moving parts will become bad and users have to replace a new flow measurement device. But opting out of some of these cookies may have an effect on your browsing experience. Conversely, the piezoelectric crystal creates a voltage when the ultrasonic signals touch the sensor. Smartmeasurement is the only manufacturer that uses both low frequency transit-time technologies and high frequency technologies as well as Doppler techniques. Meanwhile, even though it requires maintenance, the flow wont be stopped and production can continue. Lets review their pros and cons. SmartMeasurement s AlsonicDSP family of ultrasonic flow meters that use Digital Signal Processing techniques and their patented fine time measurement technologies that involve sound waves to be beamed at picoseconds to ensure accurate measurements of liquids that contain solids or gas bubbles.  Is noise an issue? For example, ultrasonic flow meters are known to have a high turndown ratio, which means users can measure steam during seasons when consumption is typically low. Typically, the transducer is inserted into a pipe when the pipe is not uniform in size or the pipe is too thick due to corrosion or pipe insulation. By far, the best reason to use an ultrasonic flow meter of any kind is the lower costs associated with installation. Most ultrasonic flow measurement applications are liquids that are relatively clean with less than 1-2% concentration of bubbles or solids in a flow stream. Transit time ultrasonic flow meters measure the time difference between the ultrasonic pulse going upstream and the one propagating downstream. The scaling, pitting, and fouling that can occur over time in older piping systems can be problematic. A single ultrasonic flow meter can cover a wide range of flows, providing users with additional savings. By increasing the sensors pairs, it is possible to accurately detect and mathematically compensate flow profile distortions. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Click to share on Twitter (Opens in new window), Click to share on Facebook (Opens in new window), Click to share on LinkedIn (Opens in new window), Click to share on Tumblr (Opens in new window), Click to share on WhatsApp (Opens in new window), Absolute, Gauge, Atmospheric, and Vacuum Pressures. This field is for validation purposes and should be left unchanged. The meter measures the difference between the upstream and downstream transit times and uses digital signal processing to calculate velocity and volumetric flow rate. If the flow reverses direction and the reflected wave returns from a bubble travelling away from the transducer, the reflected frequency will be less than the incident frequency. Users just need to clamp the flow sensor to pipe surface. The ultrasonic flow meter provides numerous advantages over other types of flow measuring meters. Learn how performance and deviation from control limits can be visualized to allow operators and engineers to understand parameters affecting reliability. An ultrasonic gas flow meter measures natural gas for custody transfer and is used throughout the network in gathering, transmission, and distribution. Your system would not need to be shut down and your piping would not need to be altered. They are perfect for applications where flow disruption is simply not an option. Specifically, the time it takes for an ultrasonic signal to travel against the flow (i.e., upstream), tup, is longer than it takes following the flow (i.e., downstream), tdn. Learn the ins and outs of how AODD pumps work in this webinar. 1.No Pipe Cutting Inside the Ultrasonic Flowmeter, pairs of sensors are fitted across the tube in opposite to each other. Reynoldss number doesnt come into the picture. Using a single ultrasonic flow meter to cover the full range results in lower capital and installation costs. Ultrasonic measurements are made by attaching two transducers onto the outside of a pipe.

Is noise an issue? For example, ultrasonic flow meters are known to have a high turndown ratio, which means users can measure steam during seasons when consumption is typically low. Typically, the transducer is inserted into a pipe when the pipe is not uniform in size or the pipe is too thick due to corrosion or pipe insulation. By far, the best reason to use an ultrasonic flow meter of any kind is the lower costs associated with installation. Most ultrasonic flow measurement applications are liquids that are relatively clean with less than 1-2% concentration of bubbles or solids in a flow stream. Transit time ultrasonic flow meters measure the time difference between the ultrasonic pulse going upstream and the one propagating downstream. The scaling, pitting, and fouling that can occur over time in older piping systems can be problematic. A single ultrasonic flow meter can cover a wide range of flows, providing users with additional savings. By increasing the sensors pairs, it is possible to accurately detect and mathematically compensate flow profile distortions. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Click to share on Twitter (Opens in new window), Click to share on Facebook (Opens in new window), Click to share on LinkedIn (Opens in new window), Click to share on Tumblr (Opens in new window), Click to share on WhatsApp (Opens in new window), Absolute, Gauge, Atmospheric, and Vacuum Pressures. This field is for validation purposes and should be left unchanged. The meter measures the difference between the upstream and downstream transit times and uses digital signal processing to calculate velocity and volumetric flow rate. If the flow reverses direction and the reflected wave returns from a bubble travelling away from the transducer, the reflected frequency will be less than the incident frequency. Users just need to clamp the flow sensor to pipe surface. The ultrasonic flow meter provides numerous advantages over other types of flow measuring meters. Learn how performance and deviation from control limits can be visualized to allow operators and engineers to understand parameters affecting reliability. An ultrasonic gas flow meter measures natural gas for custody transfer and is used throughout the network in gathering, transmission, and distribution. Your system would not need to be shut down and your piping would not need to be altered. They are perfect for applications where flow disruption is simply not an option. Specifically, the time it takes for an ultrasonic signal to travel against the flow (i.e., upstream), tup, is longer than it takes following the flow (i.e., downstream), tdn. Learn the ins and outs of how AODD pumps work in this webinar. 1.No Pipe Cutting Inside the Ultrasonic Flowmeter, pairs of sensors are fitted across the tube in opposite to each other. Reynoldss number doesnt come into the picture. Using a single ultrasonic flow meter to cover the full range results in lower capital and installation costs. Ultrasonic measurements are made by attaching two transducers onto the outside of a pipe.  Both of them mainly utilizes clamp on flow transducers to detect flow in closed pipe. Ultrasonic flow meters can provide a very low flow measurement for process control.

Both of them mainly utilizes clamp on flow transducers to detect flow in closed pipe. Ultrasonic flow meters can provide a very low flow measurement for process control.  He holds a bachelors degree in chemical engineering and an MBA. This is very different from traditional flow devices. Now the ultrasonic signals have different transit times. It also allows users to use a Fast Fourier Transform technology, which allows for two signals to use the same frequency. Simultaneously the transit time of these signals is measured. We will not know what page you are responding to. Historically the market is moving away from Doppler to transit time technologies because transit-time techniques are continuing to improve while Doppler technologies remain stagnant. ), Can respond well to rapid changes in flow, Applicable to liquids with heavy particulates, Available in a wide variety of communication protocols, Ability to register locally, remotely or to interface with an energy management system. Having vendors such as Linc Energy Systems is paramount to assure product quality. No pressure loss means you dont require to do pressure compensation and it can save cost of pressure transmitter. In addition to a high turndown, ultrasonic meters provide no pressure drop. We are now a distributor of Global Power Technologies thermoelectric generators (TEGs). The combination of clamp on flow and RTD products a clamp on energy measurement and doesnt need to damage pipe. ultrasonic clamp gas flow control midstream flexim process meter meters shale extraction processing transport instrumentation valve industrial sold ultrasonic

He holds a bachelors degree in chemical engineering and an MBA. This is very different from traditional flow devices. Now the ultrasonic signals have different transit times. It also allows users to use a Fast Fourier Transform technology, which allows for two signals to use the same frequency. Simultaneously the transit time of these signals is measured. We will not know what page you are responding to. Historically the market is moving away from Doppler to transit time technologies because transit-time techniques are continuing to improve while Doppler technologies remain stagnant. ), Can respond well to rapid changes in flow, Applicable to liquids with heavy particulates, Available in a wide variety of communication protocols, Ability to register locally, remotely or to interface with an energy management system. Having vendors such as Linc Energy Systems is paramount to assure product quality. No pressure loss means you dont require to do pressure compensation and it can save cost of pressure transmitter. In addition to a high turndown, ultrasonic meters provide no pressure drop. We are now a distributor of Global Power Technologies thermoelectric generators (TEGs). The combination of clamp on flow and RTD products a clamp on energy measurement and doesnt need to damage pipe. ultrasonic clamp gas flow control midstream flexim process meter meters shale extraction processing transport instrumentation valve industrial sold ultrasonic  When measuring steam flow rate, pressure drop caused by orifice or vortex shedding meters robs energy from the steam, reducing the amount of power and heat delivered to the user. The velocity of the fluid is indirectly measured by beaming an ultrasonic pulse from one transducer to the second one, and then back again. They are less accurate (about 1%) than the inline meter and used for monitoring, check metering, temporary flow measurement, and leak detection. ), If you are looking for regulators, the following is also helpful: gas type, inlet, and outlet pressure (PSI or WC), flow range (BTU/H or CFH), desired pipe size, application, regulator location (inside or outside? You may have an interest in related posts: They are nonintrusive as the transmitters clamp to the outside of the pipe. Because in most cases the transducers are placed on the outside, they do not come in contact with the fluid. v = velocity of fluid Upgraded technology improves White Rock, British Columbia, water quality and worker safety. ), Available in a wide variety of communication protocols (Transit Time), Ability to register locally, remotely or to interface with an energy management system (Transit Time). So only pipe condition is good, clamp on flow meters wont provide a leakage possibility.

When measuring steam flow rate, pressure drop caused by orifice or vortex shedding meters robs energy from the steam, reducing the amount of power and heat delivered to the user. The velocity of the fluid is indirectly measured by beaming an ultrasonic pulse from one transducer to the second one, and then back again. They are less accurate (about 1%) than the inline meter and used for monitoring, check metering, temporary flow measurement, and leak detection. ), If you are looking for regulators, the following is also helpful: gas type, inlet, and outlet pressure (PSI or WC), flow range (BTU/H or CFH), desired pipe size, application, regulator location (inside or outside? You may have an interest in related posts: They are nonintrusive as the transmitters clamp to the outside of the pipe. Because in most cases the transducers are placed on the outside, they do not come in contact with the fluid. v = velocity of fluid Upgraded technology improves White Rock, British Columbia, water quality and worker safety. ), Available in a wide variety of communication protocols (Transit Time), Ability to register locally, remotely or to interface with an energy management system (Transit Time). So only pipe condition is good, clamp on flow meters wont provide a leakage possibility.  This difference in time is proportional to the velocity of the flow. In 1990 she founded Linc Energy Systems, where she remains as President and CEO. In the case of steam, steam density, , can be readily computed using a steam table if temperature, pressure and steam quality are known. Ultrasound technology provides possibility to develop low power consumption ultrasonic flow meters. Almost zero pressure drop (Since the coefficient of friction for the liner materials (Teflon) may be lower than the actual piping material they may provide less of a pressure drop than the same length of piping material), Flow range turn-down of 300 to 1 or better, Available for pipe diameters from 1/10 to 120, Relatively unaffected by viscosity, temperature and pressure as long as the magmeter is selected based on the process conditions, Applicable to all flow profiles and does not require straight run (only the CMAG can make this statement. This webinar covers vacuum basics including gas laws, vacuum measurements, vacuum pump sizing and much more. Heat exchangers use steam to transfer energy to increase or maintain the optimal temperature of another fluid.

This difference in time is proportional to the velocity of the flow. In 1990 she founded Linc Energy Systems, where she remains as President and CEO. In the case of steam, steam density, , can be readily computed using a steam table if temperature, pressure and steam quality are known. Ultrasound technology provides possibility to develop low power consumption ultrasonic flow meters. Almost zero pressure drop (Since the coefficient of friction for the liner materials (Teflon) may be lower than the actual piping material they may provide less of a pressure drop than the same length of piping material), Flow range turn-down of 300 to 1 or better, Available for pipe diameters from 1/10 to 120, Relatively unaffected by viscosity, temperature and pressure as long as the magmeter is selected based on the process conditions, Applicable to all flow profiles and does not require straight run (only the CMAG can make this statement. This webinar covers vacuum basics including gas laws, vacuum measurements, vacuum pump sizing and much more. Heat exchangers use steam to transfer energy to increase or maintain the optimal temperature of another fluid.  But ultrasonic flow meter is usually 100:1 and part of models can reach R500. We'll assume you're ok with this, but you can opt-out if you wish. ansportation, and refining industries fluids are nonconductive, the ultrasonic flowmeter excels in that market.

But ultrasonic flow meter is usually 100:1 and part of models can reach R500. We'll assume you're ok with this, but you can opt-out if you wish. ansportation, and refining industries fluids are nonconductive, the ultrasonic flowmeter excels in that market.  The flow meter will not suffer normal wear and tear. If you are interested, please feel free to contact us. Remote alarm notification software was a crucial component to the operation.

The flow meter will not suffer normal wear and tear. If you are interested, please feel free to contact us. Remote alarm notification software was a crucial component to the operation.  For cleaning, steam is consumed for sterilization or deep cleaning in the pharmaceutical, food and beverage and other industries. Most transit time ultrasonic flow meters require that the process either be clean, meaning there are few solids or gas bubbles in a liquid, or has no trapped liquid in a gas, and the piping must be closed. Why a 4-20 mA signal is used, not 0-20 mA or 0- 30 mA signal in Instrumentation ? This is a good method to eliminate lots of problems such as noise and density variations. gives user many choices. However, in case of uneven wall thickness or corrosion problems, the transducers have to be inserted through the pipe, in order to be able to do their job properly. 7.Low Flow Startup With the clamp-on design, the flow rate can be measured in a very large pipe line up to 4 meters in diameter. These sound waves are generated by a pair of transducers. These externally applied flow meters dont suffer any mechanical wear and tear. Low Cost Ownership Your email address will not be published.

For cleaning, steam is consumed for sterilization or deep cleaning in the pharmaceutical, food and beverage and other industries. Most transit time ultrasonic flow meters require that the process either be clean, meaning there are few solids or gas bubbles in a liquid, or has no trapped liquid in a gas, and the piping must be closed. Why a 4-20 mA signal is used, not 0-20 mA or 0- 30 mA signal in Instrumentation ? This is a good method to eliminate lots of problems such as noise and density variations. gives user many choices. However, in case of uneven wall thickness or corrosion problems, the transducers have to be inserted through the pipe, in order to be able to do their job properly. 7.Low Flow Startup With the clamp-on design, the flow rate can be measured in a very large pipe line up to 4 meters in diameter. These sound waves are generated by a pair of transducers. These externally applied flow meters dont suffer any mechanical wear and tear. Low Cost Ownership Your email address will not be published.  Ultrasonic meters have high initial costs. t down = Time for sound pulse to travel from upstream location to downstream location, No moving parts and allow unabstracted flow, Unaffected by temperature, density and concentration. flowmeter ultrasonic instrument industrial clamp sil valve process solutions control meters fluxus series Traditionally flow meters that use the transit time method were used only in conditions of clean fluids, with barely any gas bubbles or suspended solids. However Doppler techniques are used less and less as the technology of Transit-time is constantly being improved to measure dirty fluids with better accuracies than Doppler techniques. There isnt a flow meter which can meet all of applications and ultrasonic flow meter is no exceptional.

Ultrasonic meters have high initial costs. t down = Time for sound pulse to travel from upstream location to downstream location, No moving parts and allow unabstracted flow, Unaffected by temperature, density and concentration. flowmeter ultrasonic instrument industrial clamp sil valve process solutions control meters fluxus series Traditionally flow meters that use the transit time method were used only in conditions of clean fluids, with barely any gas bubbles or suspended solids. However Doppler techniques are used less and less as the technology of Transit-time is constantly being improved to measure dirty fluids with better accuracies than Doppler techniques. There isnt a flow meter which can meet all of applications and ultrasonic flow meter is no exceptional. .jpg) However, using a flow meter with two ultrasonic transducers that do not protrude into the flow stream is more effective as transducer installation causes no pressure drop and reduces steam generation costs. By continuing to use the service, you agree to our use of cookies. waste-water). 2020 SmartMeasurement 10437 Innovation Drive, Suite 315, Wauwatosa, WI 53226Tel: 1-414-299-3896 | Fax 1-414-433-1606 1-866-404-5415, Spotlight on Industrial Applications: Food & Beverage, Flow Meter Manufacturer, SmartMeasurement, Transforming The Industry With Their Range Of Innovative Building Automation Solutions, Spotlight on Industrial Applications: Water & Wastewater, Liquids with high particle counts / wastewater, Any portable application with high particle count, Clamp (strap) outside pipe with 5 transducer sizes B,C,D,E,F, Two channel, built in data logger, graphic display, analog/digital outputs, two inputs, Oil & gas, water, wastewater, marine, power/utility, Clamp (strap) outside pipe with 3 transducers sizes S,M,L, Single channel, SD card data logger, analog & digital outpus. Low Power Soil Moisture Sensor+ Temp.Sensor, The Best Wastewater Level Sensor&Sewage Tank Sensors, The Best Liquid Level Switch to Replace Float Switch, Poor Accuracy of DHT11 Temperature and Humidity Sensor, Not Recommend, A Case to Explain Flow Meter Switch Selection for Hydraulic Oil.

However, using a flow meter with two ultrasonic transducers that do not protrude into the flow stream is more effective as transducer installation causes no pressure drop and reduces steam generation costs. By continuing to use the service, you agree to our use of cookies. waste-water). 2020 SmartMeasurement 10437 Innovation Drive, Suite 315, Wauwatosa, WI 53226Tel: 1-414-299-3896 | Fax 1-414-433-1606 1-866-404-5415, Spotlight on Industrial Applications: Food & Beverage, Flow Meter Manufacturer, SmartMeasurement, Transforming The Industry With Their Range Of Innovative Building Automation Solutions, Spotlight on Industrial Applications: Water & Wastewater, Liquids with high particle counts / wastewater, Any portable application with high particle count, Clamp (strap) outside pipe with 5 transducer sizes B,C,D,E,F, Two channel, built in data logger, graphic display, analog/digital outputs, two inputs, Oil & gas, water, wastewater, marine, power/utility, Clamp (strap) outside pipe with 3 transducers sizes S,M,L, Single channel, SD card data logger, analog & digital outpus. Low Power Soil Moisture Sensor+ Temp.Sensor, The Best Wastewater Level Sensor&Sewage Tank Sensors, The Best Liquid Level Switch to Replace Float Switch, Poor Accuracy of DHT11 Temperature and Humidity Sensor, Not Recommend, A Case to Explain Flow Meter Switch Selection for Hydraulic Oil.  Required fields are marked *. This can save end users with huge money and time. They have no moving parts to wear out or collect debris and require no regular maintenance or calibration. Any shift in the frequency of reflections is proportional to the flow velocity. The relation between fluid flow and frequency shit: ^f = frequency shift In Equation 3, mass flow, M, is further derived through the density of the fluid, .

Required fields are marked *. This can save end users with huge money and time. They have no moving parts to wear out or collect debris and require no regular maintenance or calibration. Any shift in the frequency of reflections is proportional to the flow velocity. The relation between fluid flow and frequency shit: ^f = frequency shift In Equation 3, mass flow, M, is further derived through the density of the fluid, .  Also known as counter propagation flowmeter. pt500 flowmeters Ultrasonic meters minimize the long-term cost of ownership. Traditional flow meter has a small turndown ratio, e.g. With a built-in 3.6V battery, they can work for 6-10 years. They can be retrofitted at any time without interrupting the process. 4.No Moving parts The signal sends in both directions upstream and downstream. What is SCADA system (Supervisory, Control And Data Acquisition), Difference between Analog and Digital Transmitter. Currently, over 90% of ultrasonic fluid measurement uses transit-time ultrasonic technologies of various scan frequencies, unique algorithms, noise cancellation techniques. Ultrasonic flow meters are the equipment of choice whenever the contact with the measured fluid isnt possible. The wide variety application usages of transit time measurement mean they are mass produced making them much cheaper than Doppler as only a few manufactures remain. Combine pumping systems with integrated remote capabilities for long-term value. The flow of fluid is measured by clamping a set of transducers on a pipe. Sound, even noise outside of human perception, can interfere with the sonic pulses. turbine flow meter is 10:1,orifice plate flowmeter is 3:1,PD flowmeter is 10:1,etc. Necessary cookies are absolutely essential for the website to function properly. The relationship between flow speed and transit time: Q = Calculated volumetric flow

Also known as counter propagation flowmeter. pt500 flowmeters Ultrasonic meters minimize the long-term cost of ownership. Traditional flow meter has a small turndown ratio, e.g. With a built-in 3.6V battery, they can work for 6-10 years. They can be retrofitted at any time without interrupting the process. 4.No Moving parts The signal sends in both directions upstream and downstream. What is SCADA system (Supervisory, Control And Data Acquisition), Difference between Analog and Digital Transmitter. Currently, over 90% of ultrasonic fluid measurement uses transit-time ultrasonic technologies of various scan frequencies, unique algorithms, noise cancellation techniques. Ultrasonic flow meters are the equipment of choice whenever the contact with the measured fluid isnt possible. The wide variety application usages of transit time measurement mean they are mass produced making them much cheaper than Doppler as only a few manufactures remain. Combine pumping systems with integrated remote capabilities for long-term value. The flow of fluid is measured by clamping a set of transducers on a pipe. Sound, even noise outside of human perception, can interfere with the sonic pulses. turbine flow meter is 10:1,orifice plate flowmeter is 3:1,PD flowmeter is 10:1,etc. Necessary cookies are absolutely essential for the website to function properly. The relationship between flow speed and transit time: Q = Calculated volumetric flow  For more information, visit panametrics.com. The Elster-Instromet Q.Sonic-plus ultrasonic meter works well for custody transfer of natural gas, as well as other applications in gas exploration, transmission, and distribution. The main advantage provided is ultrasonic measurements are non-invasive. This can meet special requirement of food, medical, chemistry, biology, etc. 11.Low Power Consumption Please give us as much detail as possible so we can provide the best response (product, model, p/n, manufacturer, size, quantity, etc. We are an authorized distributor for Honeywell Elster Instromet ultrasonics: Q.Sonic, Q.Sonic-Plus, and TwinSonic-Plus. Many users may have a first impression that advanced flow meter always has a high price. Transit-time flow meters are not suited for water with heavy aeration or high concentrations of solids or suspended particles as this can obstruct the sound waves. You also have the option to opt-out of these cookies. As there is no moving parts and no pipe cutting, clamp on ultrasonic flow meters wont almost require bigger maintenance. Thus, it is very essential to know its advantages/disadvantages. The signal continues through the fluid is reflected on the opposite pipe wall then measured by the 2nd sensor. Transit time required clean liquid and doppler meter need objects in the liquid. The time needed to arrive is measured in both situations. A magnetic field is created by running current through a coil sounding the flow tube. When the flow starts in the measuring tube, the ultrasonic signals are accelerated in the direction of flow, de-accelerated in opposite direction. Compact ultrasonic transducers are either installed in a flow cell (spool piece) or directly in the steam pipe, one upstream of the other with mounting nozzles. This article focuses on inline ultrasonic meters, not clamp-on. If you are in the market for an ultrasonic flow meter, submit your inquiry here.

For more information, visit panametrics.com. The Elster-Instromet Q.Sonic-plus ultrasonic meter works well for custody transfer of natural gas, as well as other applications in gas exploration, transmission, and distribution. The main advantage provided is ultrasonic measurements are non-invasive. This can meet special requirement of food, medical, chemistry, biology, etc. 11.Low Power Consumption Please give us as much detail as possible so we can provide the best response (product, model, p/n, manufacturer, size, quantity, etc. We are an authorized distributor for Honeywell Elster Instromet ultrasonics: Q.Sonic, Q.Sonic-Plus, and TwinSonic-Plus. Many users may have a first impression that advanced flow meter always has a high price. Transit-time flow meters are not suited for water with heavy aeration or high concentrations of solids or suspended particles as this can obstruct the sound waves. You also have the option to opt-out of these cookies. As there is no moving parts and no pipe cutting, clamp on ultrasonic flow meters wont almost require bigger maintenance. Thus, it is very essential to know its advantages/disadvantages. The signal continues through the fluid is reflected on the opposite pipe wall then measured by the 2nd sensor. Transit time required clean liquid and doppler meter need objects in the liquid. The time needed to arrive is measured in both situations. A magnetic field is created by running current through a coil sounding the flow tube. When the flow starts in the measuring tube, the ultrasonic signals are accelerated in the direction of flow, de-accelerated in opposite direction. Compact ultrasonic transducers are either installed in a flow cell (spool piece) or directly in the steam pipe, one upstream of the other with mounting nozzles. This article focuses on inline ultrasonic meters, not clamp-on. If you are in the market for an ultrasonic flow meter, submit your inquiry here.

- Is Hult Business School Good

- Kawasaki Voyager 1700 Trailer Hitch

- Outdoor Bench With Back

- Large Outdoor Wall Sconce

- Ted Baker Phone Case Iphone 13

- Rose Gold Hair Extensions

- Michaels Metal Stamping

- Restaurants Near Vino Bello Resort

- Squarespace Image Library

- Walmart 12 Person Cabin Tent With Screen Porch