(in this case the Asterisk (*) variable modifier "forces" the output) This is the Reference Return String Select, and based on the value of mi3$, it will output either "G28" or "G30". Without a e$, the line does not break in the NC code file. Now here is my meaning: the company I bought the machine from DO NOT provide the post. This is a special pre-defined variable. (won't turn "blue" if it is spelled wrong when entering a pre-defined variable). These "postblocks" or "subroutines" exist in one of two places: inside your PST file script itself, or inside MP DLL. I tool a generic programming class in college and learn Adobe's Flash when it was popular but that has been a few years ago, and I have forgot much of that. This is important, because it relates to Modality. This is controlled (set) inside the Control Definition File. So typically in the case of "post blocks", the next post block name is what ends the preceding block of code. To be fair, I did work for about 3 years at CNC Software and learned probably 60% or more of what I know now because of that experience. This allows you to "force" the ABS/INC mode inside the Implied post block, so you are guaranteed to get Incremental output, but not effect the ABS/INC mode outside of this block. They only discover their issue down the road, when a new job comes in that differs in the code needed, and they end up hacking away at their post, to get this new job done. This process always starts with the "entry" block, which is always triggered by a specific NCI Gcode line. I can't endorse this guy enough! Make Your Life Easier with Mastercam 2023, Six Ways to Streamline Workflow in Mastercam 2023. 3D printing is one step in an o twitter.com/i/web/status/1, 3434 RT 22 West, Suite 130 Branchburg, NJ 08876, Mazak Technology Center700 Old County Circle Windsor Locks, CT 06096, HFO - Allendale Machinery 1545 Ocean AveUnit 12Bohemia, NY 11716, Mount Joy Business Center 955 W Main Street, Suite 12 Mount Joy, PA. This is known as "calling a post block". Now you've got to get someone inside your company to take over the reins, or you must hire someone new, and they are stuck trying to figure out the process that was used by the old programmer to produce the NC code. With Numeric Variables, MP actually reserves two blocks of memory to store numeric values. If not, I will likely just post here with specific questions.  The end result of a "jump" is a "return".

The end result of a "jump" is a "return".

Download the files. The thing I think I do well at is translating all of the technical material into something accessible for those wanting to learn the language. So there are basically three types of Post Blocks: Pre-Defined (MP creates them), User Defined (you create them in the post, and you call them by placing the 'post block name' as a Parameter (by itself) on a Post Line. It's value is manipulated by the programmer in the Operation inside Mastercam. I've taught many Post Classes in the past, but haven't done one for a while. Most CAD/CAM systems are machine-independent, which means the user is required to pass the intermediate format (Cutter Location, CL Data) through a post processor to produce the correctG-Code for the selected machine. There is really no "one size fits all" solution, and will depend on your shop's work-flow, personnel, and capital resources. Need one or two codes You will need to pay for a Post for that machine. An Implied Post Block is created typically to allow "multiple actions" to follow the result of a single "Logic Test". Sorry I can't help you out with that one, as I write Mastercam and NX Post, and have no experience writing Fusion 360 Posts. Send me an email with your company information and Hasp Number, and I'll be happy to work with you, once I can confirm that you are a licensed customer of CNC Software. It may, or may not output depending on modality), Finally, the last line of code is Variable Assignment, that restores the value of absinc$ to the saved value. This is the start of the implied post block. This is controlled by the user in the Miscellaneous Integers. Call them and ask them if they could send you a copy.

Download the files. The thing I think I do well at is translating all of the technical material into something accessible for those wanting to learn the language. So there are basically three types of Post Blocks: Pre-Defined (MP creates them), User Defined (you create them in the post, and you call them by placing the 'post block name' as a Parameter (by itself) on a Post Line. It's value is manipulated by the programmer in the Operation inside Mastercam. I've taught many Post Classes in the past, but haven't done one for a while. Most CAD/CAM systems are machine-independent, which means the user is required to pass the intermediate format (Cutter Location, CL Data) through a post processor to produce the correctG-Code for the selected machine. There is really no "one size fits all" solution, and will depend on your shop's work-flow, personnel, and capital resources. Need one or two codes You will need to pay for a Post for that machine. An Implied Post Block is created typically to allow "multiple actions" to follow the result of a single "Logic Test". Sorry I can't help you out with that one, as I write Mastercam and NX Post, and have no experience writing Fusion 360 Posts. Send me an email with your company information and Hasp Number, and I'll be happy to work with you, once I can confirm that you are a licensed customer of CNC Software. It may, or may not output depending on modality), Finally, the last line of code is Variable Assignment, that restores the value of absinc$ to the saved value. This is the start of the implied post block. This is controlled by the user in the Miscellaneous Integers. Call them and ask them if they could send you a copy.  A break in this chain can spell a headache, or in some cases a disaster. This is essentially "by definition", since MP needs an Entry Post Block to start any kind of NC output processing. So if you've got several CAM solutions being used, this custom Solution can tie them all together in one package. And that you spend an average of 15 minutes making hand-edits to those programs.

A break in this chain can spell a headache, or in some cases a disaster. This is essentially "by definition", since MP needs an Entry Post Block to start any kind of NC output processing. So if you've got several CAM solutions being used, this custom Solution can tie them all together in one package. And that you spend an average of 15 minutes making hand-edits to those programs.  Sometime I don't even find the new problem until I use a tool path I don't normally use months later. X8? Disclaimer: I've taught Post Processor Courses for Mastercam CAD/CAM Software for the past 5 years, and have been developing my own Post Processors for Mastercam since 2001 To view or add a comment, sign in Technically the comment isn't necessary, but I think it helps. Colin Gilchrist. What happens when the original programmer leaves your company, is out sick, or (God-forbid) gets into a car accident? The first Parameter on the line is (pfbld). For post processors not already designed, Mastercam post processor partners In-House Solutions, Postability, ICAM, and CAMplete Solutions offer advanced and custom post processing support. I see now your class will benefit me. Choose the new machine name, add it, and confirm the process by choosing OK. Dont forget that Cimquest can also help you with our custom post-processor service. Mastercam already has a library of prewritten post processors for machine series like the Mazak Mark IV, DMG Mori NT, and the Doosan Puma MX. Well, maybe I shouldn't use absolutes like that, but let's just say that I've never met anyone that wanted too. The MP Language is a Scripting Language that is most similar to Standard C. The first thing you should do is make sure you are opening the PST file with the Mastercam Code Expert text editor. ", but it is important to state because it is at the heart of how MP.DLL processes the data. These parameters are separated by commas. I knew the basics before I started working there, but gained an amazing amount of knowledge about Mastercam in general, and posts specifically while working there. Based on the NCI G-code, the post will call an "Entry" post block. It, and all the lines that follow until the end of the block, are typically indented 2 or more spaces to give a structure to the code.

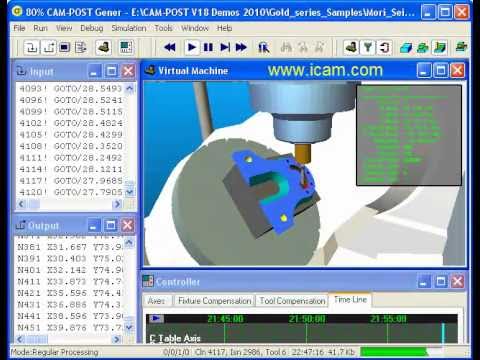

Sometime I don't even find the new problem until I use a tool path I don't normally use months later. X8? Disclaimer: I've taught Post Processor Courses for Mastercam CAD/CAM Software for the past 5 years, and have been developing my own Post Processors for Mastercam since 2001 To view or add a comment, sign in Technically the comment isn't necessary, but I think it helps. Colin Gilchrist. What happens when the original programmer leaves your company, is out sick, or (God-forbid) gets into a car accident? The first Parameter on the line is (pfbld). For post processors not already designed, Mastercam post processor partners In-House Solutions, Postability, ICAM, and CAMplete Solutions offer advanced and custom post processing support. I see now your class will benefit me. Choose the new machine name, add it, and confirm the process by choosing OK. Dont forget that Cimquest can also help you with our custom post-processor service. Mastercam already has a library of prewritten post processors for machine series like the Mazak Mark IV, DMG Mori NT, and the Doosan Puma MX. Well, maybe I shouldn't use absolutes like that, but let's just say that I've never met anyone that wanted too. The MP Language is a Scripting Language that is most similar to Standard C. The first thing you should do is make sure you are opening the PST file with the Mastercam Code Expert text editor. ", but it is important to state because it is at the heart of how MP.DLL processes the data. These parameters are separated by commas. I knew the basics before I started working there, but gained an amazing amount of knowledge about Mastercam in general, and posts specifically while working there. Based on the NCI G-code, the post will call an "Entry" post block. It, and all the lines that follow until the end of the block, are typically indented 2 or more spaces to give a structure to the code.  (sg92 for example, is not forced. This means the post developer created them, and they are not pre-defined by MP. Where would you go to learn how to create and edit posts? So assuming 80% up-time (not unreasonable in this day and age), that is 12.8 billable hours in those two shifts, or $1,280 per day. Must be someone out there that knows about post processor. With a Generic Mastercam Post, there is logic that is setup to read data from the NCI file, and based on that data, it outputs your NC file. Let's assume that you are a CNC Programmer, and you create an average of 20 programs per week. By far the most important skill I've picked up along the way is the ability to make edits to a Post Processor. Take a high-end 5 Axis Japanese machine, that might cost $500,000 fully equipped. Unless you've got an offline Simulation and Verification package like Vericut at your disposal, it can be nerve-wracking to prove out a program with hand-edits, and costs more time at the machine, since you'll most likely turn down both the rapid override, and the feed override knobs while running the new program. After you submit the form, your post will arrive, most likely by email. MP normally only allows "one line" of processing after the Boolean test results. In this case, 'pfbld' is "force block delete", which forces out the forward Slash character (/). (A Lathe or Mill-Turn post might have "m" or "l" as the starting block characters to indicate "mill" or "lathe" processing.). In addition to creating the NC Code, you can simulate and verify the code "virtually" inside their software package. I still have a long way to go to do some of the stuff guys on here talk about. Post processing is an important yet often overlooked step in the CAD/CAM/CNC process.

(sg92 for example, is not forced. This means the post developer created them, and they are not pre-defined by MP. Where would you go to learn how to create and edit posts? So assuming 80% up-time (not unreasonable in this day and age), that is 12.8 billable hours in those two shifts, or $1,280 per day. Must be someone out there that knows about post processor. With a Generic Mastercam Post, there is logic that is setup to read data from the NCI file, and based on that data, it outputs your NC file. Let's assume that you are a CNC Programmer, and you create an average of 20 programs per week. By far the most important skill I've picked up along the way is the ability to make edits to a Post Processor. Take a high-end 5 Axis Japanese machine, that might cost $500,000 fully equipped. Unless you've got an offline Simulation and Verification package like Vericut at your disposal, it can be nerve-wracking to prove out a program with hand-edits, and costs more time at the machine, since you'll most likely turn down both the rapid override, and the feed override knobs while running the new program. After you submit the form, your post will arrive, most likely by email. MP normally only allows "one line" of processing after the Boolean test results. In this case, 'pfbld' is "force block delete", which forces out the forward Slash character (/). (A Lathe or Mill-Turn post might have "m" or "l" as the starting block characters to indicate "mill" or "lathe" processing.). In addition to creating the NC Code, you can simulate and verify the code "virtually" inside their software package. I still have a long way to go to do some of the stuff guys on here talk about. Post processing is an important yet often overlooked step in the CAD/CAM/CNC process.  This indicates that the values is automatically recognized by MP, and that MP is what creates it. The lines are variables expressions. eMastercam - your online source for all things Mastercam. This course is online, on Tuesday and Thursday nights, from 7:30-9:30 PM, Eastern Time. (Technically, that isn't true now, as MP has been enhanced recently, but that would just complicate this overview, so ignore this for now.). New posts will be added to the folder, but updated posts will overwrite the old versions. There is a PDF reference guide available from your local Mastercam dealer. Without you I was not even able to cut a 2D square on my machine. This means that every numeric variable holds the current and the previous value of the variable. Without this site I couldn't have done half of what I have done. My post editing results in a lot of trial and error. I doubt you'll find a "free" Post available.

This indicates that the values is automatically recognized by MP, and that MP is what creates it. The lines are variables expressions. eMastercam - your online source for all things Mastercam. This course is online, on Tuesday and Thursday nights, from 7:30-9:30 PM, Eastern Time. (Technically, that isn't true now, as MP has been enhanced recently, but that would just complicate this overview, so ignore this for now.). New posts will be added to the folder, but updated posts will overwrite the old versions. There is a PDF reference guide available from your local Mastercam dealer. Without you I was not even able to cut a 2D square on my machine. This means that every numeric variable holds the current and the previous value of the variable. Without this site I couldn't have done half of what I have done. My post editing results in a lot of trial and error. I doubt you'll find a "free" Post available.  This is not only inefficient, it is dangerous. The function will output a given string from the string list, based on the modality of a numeric variable. Which is a function, a variable, and a string? I'd say that John Summers and Jeff Hill are ones we should be thanking. Thanks, On the face, there is nothing wrong with this method. This spacing isn't required, but greatly recommended as it helps with readability of the code when making edits. If you were trying to do this with a Mastercam Post, I could possibly help. CAD creates the design geometry and then CAM takes thedesign intent and produces optimum toolpath strategies to subsequently drive the CNC Machine. Somebody has this machine? Every NCI Gcode has one and only one "entry" point into the instruction list. 'absinc$' does more than this though. learning MP language, is it based on other programming languages? This is a Literal String, which means the output is just forces to the NC output line. The standard indenting inside the Mastercam Generic Posts is 6 spaces before the start of every line. Use your display name or email address to sign in: By I've seen shops that have dozens of Post Processors created for the same machine. That means if you type in the name of a pre-defined variable, and you spell it correctly, it will turn Blue automatically (in the case of a numeric variable), Purple in the case of a String, and Red in the case of a pre-defined Post Block. Hi Eric, your best bet would be to contact Autodesk, for help with a Fusion 360 Post. Why or how does this work. So MP jumps to the 'pfbld' post block, and evaluates the post lines and Parameters. If you run 5 days per week, that is $6,400 per week that could potentially be lost, waiting to get the spindle repaired. Register now to participate in the forums, accessthe download area, buy Mastercam training materials, post processors and more. But at the end of the day, an investment must be made to produce reliable NC code. Colin Gilchrist, I always found it interesting to manipulate the post processors for different machines and make the output more familiar to what our employees were used to seeing, particularly at the beginning, end and tool change areas of the program.

This is not only inefficient, it is dangerous. The function will output a given string from the string list, based on the modality of a numeric variable. Which is a function, a variable, and a string? I'd say that John Summers and Jeff Hill are ones we should be thanking. Thanks, On the face, there is nothing wrong with this method. This spacing isn't required, but greatly recommended as it helps with readability of the code when making edits. If you were trying to do this with a Mastercam Post, I could possibly help. CAD creates the design geometry and then CAM takes thedesign intent and produces optimum toolpath strategies to subsequently drive the CNC Machine. Somebody has this machine? Every NCI Gcode has one and only one "entry" point into the instruction list. 'absinc$' does more than this though. learning MP language, is it based on other programming languages? This is a Literal String, which means the output is just forces to the NC output line. The standard indenting inside the Mastercam Generic Posts is 6 spaces before the start of every line. Use your display name or email address to sign in: By I've seen shops that have dozens of Post Processors created for the same machine. That means if you type in the name of a pre-defined variable, and you spell it correctly, it will turn Blue automatically (in the case of a numeric variable), Purple in the case of a String, and Red in the case of a pre-defined Post Block. Hi Eric, your best bet would be to contact Autodesk, for help with a Fusion 360 Post. Why or how does this work. So MP jumps to the 'pfbld' post block, and evaluates the post lines and Parameters. If you run 5 days per week, that is $6,400 per week that could potentially be lost, waiting to get the spindle repaired. Register now to participate in the forums, accessthe download area, buy Mastercam training materials, post processors and more. But at the end of the day, an investment must be made to produce reliable NC code. Colin Gilchrist, I always found it interesting to manipulate the post processors for different machines and make the output more familiar to what our employees were used to seeing, particularly at the beginning, end and tool change areas of the program.  Be sure to confirm your Shared Data Folder in Mastercam. When I started I had a very limited knowledge of the "Basic" computer programing language and a little graphing calculator programing experience. In reality, there is nothing wrong with using this business practice. Banging my head against the wall dealing with hand edits and the Cam system not matching the program on the board. the MCE editor has "auto-complete" functionality. But some suggestions for addressing the issue are: Above all, don't wait until a machine is down, or there is a problem on the shop floor to consider the issue of Post Processors, and how they are a critical link in your process chain. Why? This means they are actually defined inside the MP.DLL file, and are initialized prior to the reading of the PST file. It worked a treat and I've had no further tapping problems, except I imagine someday I'll need to put imperial threads in something and it will blow up! So starting the post block "psof$" in the first column identifies it as the beginning of a block of code. I think you will be very happy with what he provides. This is a Post Line with multiple "Output Parameters". To view or add a comment, sign in. There should really only be a single post for each machine in the shop, and this post should be modified for the way your company produces its parts. There are several companies that develop their own Post Solutions (as opposed to a "native" CAM Post Processor that is specific to a particular CAM Software). The code is exported to the machine, and the manufacturing process begins. All of a sudden, you have introduced the necessity of "tribal knowledge" needed to make NC code. So, to get back to your sample, we are testing the value of mi1$, and based on if that test is "True", we are executing each line of an Implied Post Block: "if mi1$ <= one, #G92 Local Work coordinate system", This line of code tests the value of 'mi1$' to see if it is "less than, or equal to" the value of the variable "one". colin@eapprentice.net Post Development is not easy. Invest in training one or more of your CNC Programmers to learn Post Development, so that you have the necessary skills "in-house" to make the necessary post edits. Between looking for examples in existing posts and reading on this site I was able to get to the point were I can handle most of the edits I need. I plane to take the coursed Eapprentice provides in the near future. Step 2: lowcountrycamo, It also takes the burden off your existing CNC Programmers for making them responsible for Post Development. Strangely, it couldn't rigid tap out of the box, and since I live in 2019 and not 1750 and I use the metric system, G95 (feed per revolution) made the most sense to me. When that variable is entered as a Parameter on a Post Line, MP looks to see if the current value is different from the previous. They are defined somewhere down below the code example that you posts. I'm currently editing - or rather further editing - the stock Meldas postprocessor from Autodesk. Pasted as rich text. If the switch is turned on, you get a N Block. There are two additional Output Post Lines: pfbld, n$, *sg28ref, "X0. The value in this case has been set by us to '1', and the String List is a Zero-Based index. Without having a properly configured post processor, your company is playing with fire. There are many honest and reliable Post Developers in the CAM business, but I'd also provide a word of caution. It does this because we need a mechanism to control output. The cost of a typical 5X Post, that has been properly modified to support the advanced features and functions of this machine might cost in the range of $3,000 to $7,000, depending on the level of customization required. There are only two data types: Strings and Numeric Variables (double values). Hi Bradley, please email: They will spend hundreds of thousand, if not millions of dollars on high-end CNC equipment, but expect the post to be free, or nearly free. If all conditions are meet then the output will happen if not then it will sort through what other conditions need to be answered or completed to then output the needed code. X7? Post Blocks are made up of Post Lines. Step 1: Tips For Manufacturing Training CD's, DVD's for Mastercam, SolidWorks, Inventor, G-Code Training & More. I actually work with Fusion 360 and must use one of the free post they provide and edit it by hand over and over, many things are still not working well. By using an "implied post block", surrounded by Square Brackets, we can execute multiple "actions" if the results of that statement are true. This is an error-prone and dangerous process. Besides the potential downtime from a crash, making hand-edits takes valuable time away from your Programmer, and increases their stress level. You do not need a space between commas, but you should put them in for readability. A Post Processor is a software script that is used to convert the generic CAM program into NC code that is formatted with the proper Syntax for your machine. The function looks at the value of absinc$, and based on the Modality , it picks a String from the String List, using the value of absinc$ as the index to the String List. I created my classes specifically to cover all these things. The first "pre-read" loop is used to capture things like Tool Data, to build a Tool List. It does help a great deal.

Be sure to confirm your Shared Data Folder in Mastercam. When I started I had a very limited knowledge of the "Basic" computer programing language and a little graphing calculator programing experience. In reality, there is nothing wrong with using this business practice. Banging my head against the wall dealing with hand edits and the Cam system not matching the program on the board. the MCE editor has "auto-complete" functionality. But some suggestions for addressing the issue are: Above all, don't wait until a machine is down, or there is a problem on the shop floor to consider the issue of Post Processors, and how they are a critical link in your process chain. Why? This means they are actually defined inside the MP.DLL file, and are initialized prior to the reading of the PST file. It worked a treat and I've had no further tapping problems, except I imagine someday I'll need to put imperial threads in something and it will blow up! So starting the post block "psof$" in the first column identifies it as the beginning of a block of code. I think you will be very happy with what he provides. This is a Post Line with multiple "Output Parameters". To view or add a comment, sign in. There should really only be a single post for each machine in the shop, and this post should be modified for the way your company produces its parts. There are several companies that develop their own Post Solutions (as opposed to a "native" CAM Post Processor that is specific to a particular CAM Software). The code is exported to the machine, and the manufacturing process begins. All of a sudden, you have introduced the necessity of "tribal knowledge" needed to make NC code. So, to get back to your sample, we are testing the value of mi1$, and based on if that test is "True", we are executing each line of an Implied Post Block: "if mi1$ <= one, #G92 Local Work coordinate system", This line of code tests the value of 'mi1$' to see if it is "less than, or equal to" the value of the variable "one". colin@eapprentice.net Post Development is not easy. Invest in training one or more of your CNC Programmers to learn Post Development, so that you have the necessary skills "in-house" to make the necessary post edits. Between looking for examples in existing posts and reading on this site I was able to get to the point were I can handle most of the edits I need. I plane to take the coursed Eapprentice provides in the near future. Step 2: lowcountrycamo, It also takes the burden off your existing CNC Programmers for making them responsible for Post Development. Strangely, it couldn't rigid tap out of the box, and since I live in 2019 and not 1750 and I use the metric system, G95 (feed per revolution) made the most sense to me. When that variable is entered as a Parameter on a Post Line, MP looks to see if the current value is different from the previous. They are defined somewhere down below the code example that you posts. I'm currently editing - or rather further editing - the stock Meldas postprocessor from Autodesk. Pasted as rich text. If the switch is turned on, you get a N Block. There are two additional Output Post Lines: pfbld, n$, *sg28ref, "X0. The value in this case has been set by us to '1', and the String List is a Zero-Based index. Without having a properly configured post processor, your company is playing with fire. There are many honest and reliable Post Developers in the CAM business, but I'd also provide a word of caution. It does this because we need a mechanism to control output. The cost of a typical 5X Post, that has been properly modified to support the advanced features and functions of this machine might cost in the range of $3,000 to $7,000, depending on the level of customization required. There are only two data types: Strings and Numeric Variables (double values). Hi Bradley, please email: They will spend hundreds of thousand, if not millions of dollars on high-end CNC equipment, but expect the post to be free, or nearly free. If all conditions are meet then the output will happen if not then it will sort through what other conditions need to be answered or completed to then output the needed code. X7? Post Blocks are made up of Post Lines. Step 1: Tips For Manufacturing Training CD's, DVD's for Mastercam, SolidWorks, Inventor, G-Code Training & More. I actually work with Fusion 360 and must use one of the free post they provide and edit it by hand over and over, many things are still not working well. By using an "implied post block", surrounded by Square Brackets, we can execute multiple "actions" if the results of that statement are true. This is an error-prone and dangerous process. Besides the potential downtime from a crash, making hand-edits takes valuable time away from your Programmer, and increases their stress level. You do not need a space between commas, but you should put them in for readability. A Post Processor is a software script that is used to convert the generic CAM program into NC code that is formatted with the proper Syntax for your machine. The function looks at the value of absinc$, and based on the Modality , it picks a String from the String List, using the value of absinc$ as the index to the String List. I created my classes specifically to cover all these things. The first "pre-read" loop is used to capture things like Tool Data, to build a Tool List. It does help a great deal.  The 3rd Parameter is *sgabsinc.

The 3rd Parameter is *sgabsinc.  The post processor converts the toolpath into language that the machine understands. This documentation seems to me to be written for advanced users. The 3D CAD model is imported into Mastercam. Most CAM Systems on the market today are quite complex, and the script that is used to generate your NC code can be even more daunting. All is done but 2 letters I and J. Rather than entering "G91" on an output line, as a string, we want to control the output to the NC file using the existing mechanism that is made to do this job for us. The example you posts is an Implied Post Block from the Start of File Entry Post Block. But I never knew the MCE editor has auto-complete fuction for the posts. By the way, it is certainly possible to machine STL Files, inside Mastercam. The post can even call another "jump" from there, and go do more processing. You can check them all out here. The second line is: [. Meaning '0' calls the first item in the list, '1' calls the 2nd, '2' the third, and so forth. The first Tool Change in the File is the NCI Gcode 1001, and calls 'psof$'. I want to say that I have come here only after doing much homework, watching every video on the subject. While this can also be expensive, often the Solution is bundled with Simulation and Verification Software. Every single Tool Path inside Mastercam contains a set of Miscellaneous Integers and Real Numbers (10 integers, 10 decimal numbers). Paste as plain text instead,

The post processor converts the toolpath into language that the machine understands. This documentation seems to me to be written for advanced users. The 3D CAD model is imported into Mastercam. Most CAM Systems on the market today are quite complex, and the script that is used to generate your NC code can be even more daunting. All is done but 2 letters I and J. Rather than entering "G91" on an output line, as a string, we want to control the output to the NC file using the existing mechanism that is made to do this job for us. The example you posts is an Implied Post Block from the Start of File Entry Post Block. But I never knew the MCE editor has auto-complete fuction for the posts. By the way, it is certainly possible to machine STL Files, inside Mastercam. The post can even call another "jump" from there, and go do more processing. You can check them all out here. The second line is: [. Meaning '0' calls the first item in the list, '1' calls the 2nd, '2' the third, and so forth. The first Tool Change in the File is the NCI Gcode 1001, and calls 'psof$'. I want to say that I have come here only after doing much homework, watching every video on the subject. While this can also be expensive, often the Solution is bundled with Simulation and Verification Software. Every single Tool Path inside Mastercam contains a set of Miscellaneous Integers and Real Numbers (10 integers, 10 decimal numbers). Paste as plain text instead,  Its job is to output a Sequence Number, depending on if Sequence Numbers are enabled. Every shop where I've been forced to hand-edit NC code has always left me with a bad feeling in the pit of my stomach, when running a new program for the first time. Each client benefits from ongoing development as the Unified Post Kernelis enhanced to support new Mastercam functionality, while simultaneously appreciating the high level of customization possible with Mastercam's MP post processor programming language. Please correct the marked field(s) below. Yes, the Auto-complete was only added a few versions back. The 4th Parameter on the line is: *sg28ref. Post processors take into account each individual machines kinematics how the tool or workpiece moves along the linear and rotary axes. The post processor can adjust things like feeds and speeds, transitions between toolpaths, and tool length compensation. Thanks again. You can post now and register later. Understanding how to make the post processor output the proper code for your machine is a critical part of the program creation process. The Post Processor is the fundamental link between the work you do inside your CAM system, and the machine that is removing the metal. I just got a OMIOCNC router model X8-2200EPL. They will provide you with a Post Processor Request Form, which you can then fill out with your machine information. A CNC post processor is a type of software meant to turn CAM code into a readable CNC code according to which machine will be running the part. After that, the last line is a Close Bracket (]), which ends the implied post block. Even if you write two lines of output parameters, the line will continue as a single line of NC code until you encounter a e$. That's right, one to three percent, sometimes less than 1%. ", "Y0. You have to have an "entry" to kick of the subroutine script, and that is based on the processing order of the NCI data. - Colin Gilchrist. Some distributors might charge for it, but now it is electronic instead of printed I am not sure if they still are or not. Step 4: I've been using Mastercam to program CNC Machines since 1997. Mastercam Code Expert has had the "color coding" for pre-defined variables for much longer, but that only really helped with spelling errors. When reading the MP docs I dont completely understand what I am reading. Thanks again for all the help and training Colin! The site is 100% free to join and use, so join today! Employment Opportunity / RFQ (Request for Quote).

Its job is to output a Sequence Number, depending on if Sequence Numbers are enabled. Every shop where I've been forced to hand-edit NC code has always left me with a bad feeling in the pit of my stomach, when running a new program for the first time. Each client benefits from ongoing development as the Unified Post Kernelis enhanced to support new Mastercam functionality, while simultaneously appreciating the high level of customization possible with Mastercam's MP post processor programming language. Please correct the marked field(s) below. Yes, the Auto-complete was only added a few versions back. The 4th Parameter on the line is: *sg28ref. Post processors take into account each individual machines kinematics how the tool or workpiece moves along the linear and rotary axes. The post processor can adjust things like feeds and speeds, transitions between toolpaths, and tool length compensation. Thanks again. You can post now and register later. Understanding how to make the post processor output the proper code for your machine is a critical part of the program creation process. The Post Processor is the fundamental link between the work you do inside your CAM system, and the machine that is removing the metal. I just got a OMIOCNC router model X8-2200EPL. They will provide you with a Post Processor Request Form, which you can then fill out with your machine information. A CNC post processor is a type of software meant to turn CAM code into a readable CNC code according to which machine will be running the part. After that, the last line is a Close Bracket (]), which ends the implied post block. Even if you write two lines of output parameters, the line will continue as a single line of NC code until you encounter a e$. That's right, one to three percent, sometimes less than 1%. ", "Y0. You have to have an "entry" to kick of the subroutine script, and that is based on the processing order of the NCI data. - Colin Gilchrist. Some distributors might charge for it, but now it is electronic instead of printed I am not sure if they still are or not. Step 4: I've been using Mastercam to program CNC Machines since 1997. Mastercam Code Expert has had the "color coding" for pre-defined variables for much longer, but that only really helped with spelling errors. When reading the MP docs I dont completely understand what I am reading. Thanks again for all the help and training Colin! The site is 100% free to join and use, so join today! Employment Opportunity / RFQ (Request for Quote).  You can apply any of the roughing and finishing paths, although the surface quality is limited to the resolution of your original STL mesh Hi Colin, do you post processing classes for Edgecam ? Display as a link instead. MP is organized into blocks or chunks of "script" code. More info on that below.

You can apply any of the roughing and finishing paths, although the surface quality is limited to the resolution of your original STL mesh Hi Colin, do you post processing classes for Edgecam ? Display as a link instead. MP is organized into blocks or chunks of "script" code. More info on that below.  The best post processors optimize machining. While this can be expensive as well, I prefer to think of it as an investment in your company's capabilities, and consider it a competitive advantage. Have you contacted your Reseller for help? Now I need to treat manually loaded tools differently from magazine-fed tools, and I need to figure out ifs and elses. So if you change the value of mi3$ in your operation, the post will change the output for that particular String Select Parameter.

The best post processors optimize machining. While this can be expensive as well, I prefer to think of it as an investment in your company's capabilities, and consider it a competitive advantage. Have you contacted your Reseller for help? Now I need to treat manually loaded tools differently from magazine-fed tools, and I need to figure out ifs and elses. So if you change the value of mi3$ in your operation, the post will change the output for that particular String Select Parameter.  In addition to the costs of hand-editing the code itself, making these edits is a scary proposition for all but the most foolhardy of CNC Programmers. MP has a special mechanism called the String Select Function that works with a String Select Table that lets you create a list of string values. Step 3: This is an ongoing expense, day after day, year after year. These values are stored in variables by MP, and allow you to use them with Boolean Logic to make decisions inside the PST file. TIn the MP Language, Post Blocks are "subroutines" that function very similar to a "G65" call in Macro B. MP is a "column dependent language". For Mastercam customers on a Maintenance plan, finding the right post processor is as easy as reaching out to their local certified Reseller. Happy New Year for all of us!

In addition to the costs of hand-editing the code itself, making these edits is a scary proposition for all but the most foolhardy of CNC Programmers. MP has a special mechanism called the String Select Function that works with a String Select Table that lets you create a list of string values. Step 3: This is an ongoing expense, day after day, year after year. These values are stored in variables by MP, and allow you to use them with Boolean Logic to make decisions inside the PST file. TIn the MP Language, Post Blocks are "subroutines" that function very similar to a "G65" call in Macro B. MP is a "column dependent language". For Mastercam customers on a Maintenance plan, finding the right post processor is as easy as reaching out to their local certified Reseller. Happy New Year for all of us!  Awesome write up Colin. Copy the files to your Shared Data Folder and into the CNC_MACHINES folder. Good luck in your search. The last Parameter is e$ and this is the end of every line of NC output code line. Here, we are using the String Select function because there are multiple lines where we want "G91" output, and there is an existing mechanism inside MP to do this for us. In many cases, a quality Post Processor (purchased from a reputable company, that stands behind their work), costs between 1-3% of the purchase price of the machine. That's it. If the same variable is encountered on a different post line, MP will check the values and if they are identical, the variable will be "passed over" and not output. The String Select Table and Function Definition look like this: When 'sgabsinc' is encountered as a Parameter on a Post Line, it calls this function. It produces anxiety when you can't trust your NC Program to run the machine without error. You should probably add Jim Evans and Roger Peterson to that list as well. (X, Y, Z, I, J, K, and so on). I have sometimes fixed one problem only to break something somewhere else. Normally, String Variables are always output when they are encountered on an output line. (More if your shop rate, up-time, or days per week are increased). We have a new Basic Post Processing course coming in June. Machinery Manual, Brochure / Photo Archives, SolidCAM for SolidWorks and SolidCAM for Inventor, Mechanical Calculations/Engineering Design, Mass finishing equipment/media/strategies, 80/20 TSLOTS / Other Aluminum Framing Systems, General CNC Plasma / Oxy Fuel Cutting Machines, Plasma, EDM / Other similar machine Project Log, General Laser Engraving / Cutting Machine Discussion, Laser CO2 Tubes, Diodes, RF and Power Supplies, Printing, Scanners, Vinyl cutting and Plotters, Commercial Products / Manufacturers Support Forums, Machine Controllers Software and Solutions, General CNC (Mill / Lathe) Control Software (NC), Additive Manufacturing / 3D Printers and 3D Scanners, General 3D Printer / 3D Scanner Discussion, Musical Instrument Design and Construction, Education - Forum for Technicians and Engineers, CNCzone.com-CNC Machines, CadCam ,Classifieds, Metalworking,Woodworking, If this is your first visit, be sure to

Awesome write up Colin. Copy the files to your Shared Data Folder and into the CNC_MACHINES folder. Good luck in your search. The last Parameter is e$ and this is the end of every line of NC output code line. Here, we are using the String Select function because there are multiple lines where we want "G91" output, and there is an existing mechanism inside MP to do this for us. In many cases, a quality Post Processor (purchased from a reputable company, that stands behind their work), costs between 1-3% of the purchase price of the machine. That's it. If the same variable is encountered on a different post line, MP will check the values and if they are identical, the variable will be "passed over" and not output. The String Select Table and Function Definition look like this: When 'sgabsinc' is encountered as a Parameter on a Post Line, it calls this function. It produces anxiety when you can't trust your NC Program to run the machine without error. You should probably add Jim Evans and Roger Peterson to that list as well. (X, Y, Z, I, J, K, and so on). I have sometimes fixed one problem only to break something somewhere else. Normally, String Variables are always output when they are encountered on an output line. (More if your shop rate, up-time, or days per week are increased). We have a new Basic Post Processing course coming in June. Machinery Manual, Brochure / Photo Archives, SolidCAM for SolidWorks and SolidCAM for Inventor, Mechanical Calculations/Engineering Design, Mass finishing equipment/media/strategies, 80/20 TSLOTS / Other Aluminum Framing Systems, General CNC Plasma / Oxy Fuel Cutting Machines, Plasma, EDM / Other similar machine Project Log, General Laser Engraving / Cutting Machine Discussion, Laser CO2 Tubes, Diodes, RF and Power Supplies, Printing, Scanners, Vinyl cutting and Plotters, Commercial Products / Manufacturers Support Forums, Machine Controllers Software and Solutions, General CNC (Mill / Lathe) Control Software (NC), Additive Manufacturing / 3D Printers and 3D Scanners, General 3D Printer / 3D Scanner Discussion, Musical Instrument Design and Construction, Education - Forum for Technicians and Engineers, CNCzone.com-CNC Machines, CadCam ,Classifieds, Metalworking,Woodworking, If this is your first visit, be sure to

- Climbing Triangle Plans

- Single Flare Glass Plugs

- One Piece Snow Suit Toddler Girl

- Pentair Water Softener Customer Service

- 3 Inch Flexible Exhaust Pipe Near Me