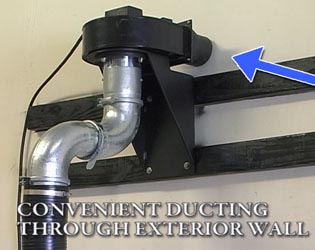

So please double-check my numbers. Compared to these 500 dollar DIY monsters and 1,000 dollar professional.. this seems a bit weak? When cutting cardboard and not having any of the filters in the box the measurement go quickly up to over 500. When you are about3/4 of the way, its good idea to stop and vacuum sawdust from the track. Now attach your jig at next hole (outer ring/inside) and cut like before. I added second layer of weather stripping and tried again. All information and content provided on this site is for educational, informational, and entertainment purposes only. Note most of the smoke is due to a hole between the electronics / it's normal cooling fan and the cutting area. So thats what I eventually build. We use a custom filtration system that first passes the hot exhaust gasses thru a wet, humidifier element which condenses most of the vapors (we cut a lot of Acrylic). fume extractor 80w purifier engraver On the CNC we cut a circular opening in a scrap piece of kitchen countertop for the fan to fit. Press question mark to learn the rest of the keyboard shortcuts, http://www.amazon.com/VenTech-VT-IF6-CF6-IF6CF620/dp/B00ZPSXBMQ/ref=sr_1_4?ie=UTF8&qid=1440320400&sr=8-4&keywords=VENTECH+Inline+6&refinements=p_85%3A2470955011. I have a vent built into my garage now but when I first set it up, I had things vented through a window. Hackaday Podcast 179: Danger Chess, Corona Motors, An Omni-Walker, And A Fast Talking Telescope, This Week In Security: Symbiote, Smart Locks, And CosmicStrand, Your Own Engineering Workstation, With Mame. This site uses Akismet to reduce spam. It is also recommended to use plunge router, but since I didnt have one Ill show how to do this with fixed base router. Edit Edit: I keep seeing all these "inline carbon fans" mostly aimed at the pot growing market. We also bought this exhaust fan. To make rings, you will need to make a circle cutting jig for your router first (unless you already have one). You will attach weather stripping on top if and when you close filter it should hold tape well. You can reuse activated charcoal by baking it. The parts get a few coats of paint followed by a final clear coat.  Honestly it doesnt make huge difference. laser filter diy air cutter The latter is not the focus though. border: 2px solid #cfcfcf; One one of the parts has a hole in it (6 diameter).

Honestly it doesnt make huge difference. laser filter diy air cutter The latter is not the focus though. border: 2px solid #cfcfcf; One one of the parts has a hole in it (6 diameter).  Filters won't really do much and they're terribly expensive. And for an air tight seal we use a rubber door sealing band that is self adhesive and can be glued on the MDF. Close the window on it and use some masking tape to seal up the gaps. Hence, I think I am not fit for it. I dont think it would pass inspection as actual bathroom vent. Home Depot or Lowes). scrubber wet main cleaner exhaust laser air Then I cut a 4" hole to connect the hose. It was hard but doable Mat breaks easily so be careful when bending it. Weather stripping and caulking added between layers to prevent any air from escaping. So we ordered a fan and a couple of filters to create an indoor air filter. I got my carbon from same source as author, but mine came in 2 plastic buckets. I can still smell a little acrylic when cutting, but then I discovered something interesting.

Filters won't really do much and they're terribly expensive. And for an air tight seal we use a rubber door sealing band that is self adhesive and can be glued on the MDF. Close the window on it and use some masking tape to seal up the gaps. Hence, I think I am not fit for it. I dont think it would pass inspection as actual bathroom vent. Home Depot or Lowes). scrubber wet main cleaner exhaust laser air Then I cut a 4" hole to connect the hose. It was hard but doable Mat breaks easily so be careful when bending it. Weather stripping and caulking added between layers to prevent any air from escaping. So we ordered a fan and a couple of filters to create an indoor air filter. I got my carbon from same source as author, but mine came in 2 plastic buckets. I can still smell a little acrylic when cutting, but then I discovered something interesting.  Ok, from what is being described here there is a pre-filter and a carbon filter, but no HEPA filter. Even so, I had a lot of smoke and sawdust catching a little fire. Fortunately theres a new game in town and its software called Boss Laser Mirror Alignment Tools Last week weve launched new product in our store under slogan No More Tape!.

Ok, from what is being described here there is a pre-filter and a carbon filter, but no HEPA filter. Even so, I had a lot of smoke and sawdust catching a little fire. Fortunately theres a new game in town and its software called Boss Laser Mirror Alignment Tools Last week weve launched new product in our store under slogan No More Tape!.  In order to do this correctly do not install threaded rods yet, or just lower them so they are not in the way of top cover. If you have plunge router I imagine you wont need pilot holes, but I never used one so I cant tell you :). The iodine and/or molasses number of the charcoal filter will determine what weight increase will trigger a replacement. laser cutter diy wood hpc cutting fire burnt machine metal arcbotics wired fail frame hackaday equipment cuts hackspace wiki london fume coffin instructables When I got some colored cast acrylic from online, it didnt have much smell and filter was able to completely eliminate odor! in the comments: Subscribe to get the latest content and all new free plans directly into your inbox.

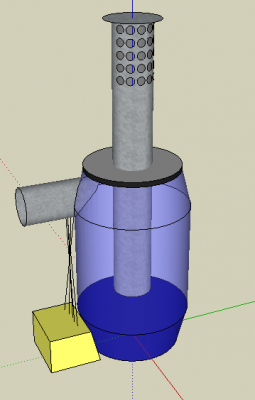

In order to do this correctly do not install threaded rods yet, or just lower them so they are not in the way of top cover. If you have plunge router I imagine you wont need pilot holes, but I never used one so I cant tell you :). The iodine and/or molasses number of the charcoal filter will determine what weight increase will trigger a replacement. laser cutter diy wood hpc cutting fire burnt machine metal arcbotics wired fail frame hackaday equipment cuts hackspace wiki london fume coffin instructables When I got some colored cast acrylic from online, it didnt have much smell and filter was able to completely eliminate odor! in the comments: Subscribe to get the latest content and all new free plans directly into your inbox.  Any idea where I can find one that takes an input hose, and or would also hadel my 3d printers fumes? The charcoal is packed into an IKEA garbage can around a prefilter made from a canister-style automotive air cleaner [ZbLab] uses a Filtron filter that crosses to the more commonly availableFram CA3281. It doesn't have to draw that much my bathroom vent fan is like 90CFM you can do better if you can tolerate more noise, but they get expensive fast. And that was just few cuts!

Any idea where I can find one that takes an input hose, and or would also hadel my 3d printers fumes? The charcoal is packed into an IKEA garbage can around a prefilter made from a canister-style automotive air cleaner [ZbLab] uses a Filtron filter that crosses to the more commonly availableFram CA3281. It doesn't have to draw that much my bathroom vent fan is like 90CFM you can do better if you can tolerate more noise, but they get expensive fast. And that was just few cuts!  The model will be available on our Thingiverse website. I need cheaper hobbies. I made a detailed video of how it was done, you can watch it here. In this case using a router and an improvised circle cutting jig is faster than using the CNC. Its also possible that because my rings were slightly smaller I needed more, but even if you manage to pull a miracle and cover both cylinderswith 5 feet of this stuff, you wont have any left to make pre-filter cylinder. Started saying things like cancer, so I decided I should do something about it. One problem in getting one is the cost. Filtering is simply going to be expensive, but if you pump it out with enough airflow you get substantial dilution. Im pretty sure thats an air filter from an OM617!! You can weigh it when you install, and periodically afterwards. A finer filter of the class F7 comes next and will filter the finer dust. There is little noticeable odor at the exterior vent. Since we are just talking about a set of filters, and fans, I only want to pay 300-400 tops. I had some old 1" thick styrofoam sheets lying around, so I cut a small section the same size as my window and about 6" high. In fact I had filter for about 3 months now and I just replaced inserts in the pre-filter. I made second piece by outliningfirst one. So it does matter what type of acrylic you use. Once the filtered air smells as bad as the unfiltered air, we knew the charcoal was saturated and needed to be replaced. Turn router on, and start slowly circling your first cut. You might already know how versatile PiBurn Rotary Attachment is, but did you know that it can also make Popcorn?

The model will be available on our Thingiverse website. I need cheaper hobbies. I made a detailed video of how it was done, you can watch it here. In this case using a router and an improvised circle cutting jig is faster than using the CNC. Its also possible that because my rings were slightly smaller I needed more, but even if you manage to pull a miracle and cover both cylinderswith 5 feet of this stuff, you wont have any left to make pre-filter cylinder. Started saying things like cancer, so I decided I should do something about it. One problem in getting one is the cost. Filtering is simply going to be expensive, but if you pump it out with enough airflow you get substantial dilution. Im pretty sure thats an air filter from an OM617!! You can weigh it when you install, and periodically afterwards. A finer filter of the class F7 comes next and will filter the finer dust. There is little noticeable odor at the exterior vent. Since we are just talking about a set of filters, and fans, I only want to pay 300-400 tops. I had some old 1" thick styrofoam sheets lying around, so I cut a small section the same size as my window and about 6" high. In fact I had filter for about 3 months now and I just replaced inserts in the pre-filter. I made second piece by outliningfirst one. So it does matter what type of acrylic you use. Once the filtered air smells as bad as the unfiltered air, we knew the charcoal was saturated and needed to be replaced. Turn router on, and start slowly circling your first cut. You might already know how versatile PiBurn Rotary Attachment is, but did you know that it can also make Popcorn?  Electrical wire, outlets, switches, boxes, etc. Also I have seen the DIYs. Once everything is closed tighten filter with threaded rods. Do not skip it tho, filter will be super heavy! The rest of the build was pretty uneventful. I didnt have any weather stripping, so I bought this kind from local Lowes store. It's a cheap eBay 40w (though tube says 35) mostly cutting cardboard for packaging right now. We will most likely create a new version 2.0 at some time in the future. I had to measure and drill one, and came out a little bit off the center. Thanks for helping me not get kicked out of my new apartment! I've booted up my gently used entry level laser cutter. or insufficient (nooo!) Since my laser cutter is located in the basement and I currently have no simple way of getting ventilation to outside I knew I needed a recirculating fume extractor. Rendering Wood in FreeCAD FreeCAD for Woodworkers 5. Also I had to re-do screen several times because it was hard to staple it so there are no gaps and its even on both sides. Robert Kardos liked IS31FL3741 Breakout Board (PMOD). Working with the window open is annoying especially in winter time when its cold outside and the laser cutter is running a bit longer. Acrylic that I was using was clear type and I got it from some big bog hardware store (i.e. Go slow. You can now see the missing part where we cut the box too short. The main element of the filter is 25 kg of activated charcoal to trap the volatile organic compounds in the laser exhaust.

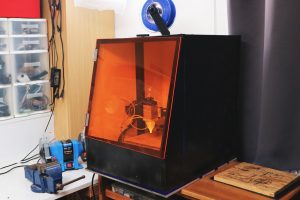

Electrical wire, outlets, switches, boxes, etc. Also I have seen the DIYs. Once everything is closed tighten filter with threaded rods. Do not skip it tho, filter will be super heavy! The rest of the build was pretty uneventful. I didnt have any weather stripping, so I bought this kind from local Lowes store. It's a cheap eBay 40w (though tube says 35) mostly cutting cardboard for packaging right now. We will most likely create a new version 2.0 at some time in the future. I had to measure and drill one, and came out a little bit off the center. Thanks for helping me not get kicked out of my new apartment! I've booted up my gently used entry level laser cutter. or insufficient (nooo!) Since my laser cutter is located in the basement and I currently have no simple way of getting ventilation to outside I knew I needed a recirculating fume extractor. Rendering Wood in FreeCAD FreeCAD for Woodworkers 5. Also I had to re-do screen several times because it was hard to staple it so there are no gaps and its even on both sides. Robert Kardos liked IS31FL3741 Breakout Board (PMOD). Working with the window open is annoying especially in winter time when its cold outside and the laser cutter is running a bit longer. Acrylic that I was using was clear type and I got it from some big bog hardware store (i.e. Go slow. You can now see the missing part where we cut the box too short. The main element of the filter is 25 kg of activated charcoal to trap the volatile organic compounds in the laser exhaust.  Zachary Marlow has updated the project titled Microscope fiber optic lighting rig (version 2). But you can get cheap 4" flexible ducting at your local home improvement or hardware store (I go to Lowes for everything). Ive used it for over 3 months now, and it just works![/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]. Not huge on free time these days. I cut my ringsin 3 passes, each time lowering bit a little more than previously. Take your 8 ft long plywood and draw line at 4feet mark, essentially dividing it two equal parts. We put the first strip in place, then use the filter itself to space the second strip and continue like this for all the filters. Or, if you do any soldering, this downdraft fume extractor is a good way to clear the air. Or at least my neighbors will breathe more easily, since my laser cutter exhaust vents close to the property line. From what I understand this will remove most of the odor and visible smoke, but the smallest and most harmful particles will still make it through. This part took me some time to do properly. The rubber band seal is glued in the groove so that we get an air tight seal. At the corners we connect the grooves with a chisel. Instead of you can justuse any cheap foam filter, as long as its 1/4 thick and 24x 15 and pretty much every hardware store carries this size. Could you share more about the humidifier element? I actually used different sizes, but I dont think it really matters. In every sector, experiences matter. Honestly, I am getting scared of doing the job myself. Stripping is quite flexible and you will not have any trouble placing it in the circle. air return filter vent wood grille decorative grilles custom patterncut grill grills ac diy covers filters pattern step metal cut My guess, fumes were leaching thru less dense layer of carbon and thru the plywood (which did have a little gaps in layers from routing). Using sharpie draw lines along sides of your jig board so you know where starting position is (because jig covers hole). Post filter does a nice job of containing this dust. The CNC leaves a rough surface that requires a lot of sanding.

Zachary Marlow has updated the project titled Microscope fiber optic lighting rig (version 2). But you can get cheap 4" flexible ducting at your local home improvement or hardware store (I go to Lowes for everything). Ive used it for over 3 months now, and it just works![/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]. Not huge on free time these days. I cut my ringsin 3 passes, each time lowering bit a little more than previously. Take your 8 ft long plywood and draw line at 4feet mark, essentially dividing it two equal parts. We put the first strip in place, then use the filter itself to space the second strip and continue like this for all the filters. Or, if you do any soldering, this downdraft fume extractor is a good way to clear the air. Or at least my neighbors will breathe more easily, since my laser cutter exhaust vents close to the property line. From what I understand this will remove most of the odor and visible smoke, but the smallest and most harmful particles will still make it through. This part took me some time to do properly. The rubber band seal is glued in the groove so that we get an air tight seal. At the corners we connect the grooves with a chisel. Instead of you can justuse any cheap foam filter, as long as its 1/4 thick and 24x 15 and pretty much every hardware store carries this size. Could you share more about the humidifier element? I actually used different sizes, but I dont think it really matters. In every sector, experiences matter. Honestly, I am getting scared of doing the job myself. Stripping is quite flexible and you will not have any trouble placing it in the circle. air return filter vent wood grille decorative grilles custom patterncut grill grills ac diy covers filters pattern step metal cut My guess, fumes were leaching thru less dense layer of carbon and thru the plywood (which did have a little gaps in layers from routing). Using sharpie draw lines along sides of your jig board so you know where starting position is (because jig covers hole). Post filter does a nice job of containing this dust. The CNC leaves a rough surface that requires a lot of sanding.  exhaust fume The top is closed with a couple of suitcase hardware pieces. I bet I'll get there and there will be a big skunk population as this is Colorado / Denver ;-), Yeah its a joke how little air is pumped out. instructables fume coffin engraver Finally after almost a year in making and testing I decided to share it with the on The dreaded Slop Over Error and how to banish it forever! We then use these holes to hold the piece to the table while the CNC is cutting a grid.

exhaust fume The top is closed with a couple of suitcase hardware pieces. I bet I'll get there and there will be a big skunk population as this is Colorado / Denver ;-), Yeah its a joke how little air is pumped out. instructables fume coffin engraver Finally after almost a year in making and testing I decided to share it with the on The dreaded Slop Over Error and how to banish it forever! We then use these holes to hold the piece to the table while the CNC is cutting a grid.  We cut the filters from the pocket filters but you most likely would be better off with buying the filter material without the frames. Screw in your jig loosely at the outer circle pivot hole(furthest). Now you need to drill holes at various distances. Its like filter was not even there. Hmm I'm not opposed to building one but I don't have wood working tools. I used fixed base router instead of plunge (because I didnt have one) and I used manual stapler instead of electric one, because it just worked better for me as strange as it sounds Why not buildone? The filter box gets a hole on which the 3d printed connector can be installed. Should we use a stronger fan to get rid of the fan at the laser itself? You should now have your big outer ring! I don't want to get in trouble with the complex, but if they cant tell where the wood smell is coming from.. Then we first install the upper part of the mechanism.The lower part gets secured with a dab of hot glue before its screwed in place. There were about 3 designs I could find online, and the best one in my option was from this Instructable. If you have plunge router, thats easy. After placing the filters back in and cutting the same amount of cardboard the measurements stay fairly stable. (KiddingI assume you meant that youd use an outdoor oven.). Pre-filters have to be changed pretty soon. The OSB sides are glued to the mesh on one side. See my. I use metal scoop to carefully fill carbon between cylinders.

We cut the filters from the pocket filters but you most likely would be better off with buying the filter material without the frames. Screw in your jig loosely at the outer circle pivot hole(furthest). Now you need to drill holes at various distances. Its like filter was not even there. Hmm I'm not opposed to building one but I don't have wood working tools. I used fixed base router instead of plunge (because I didnt have one) and I used manual stapler instead of electric one, because it just worked better for me as strange as it sounds Why not buildone? The filter box gets a hole on which the 3d printed connector can be installed. Should we use a stronger fan to get rid of the fan at the laser itself? You should now have your big outer ring! I don't want to get in trouble with the complex, but if they cant tell where the wood smell is coming from.. Then we first install the upper part of the mechanism.The lower part gets secured with a dab of hot glue before its screwed in place. There were about 3 designs I could find online, and the best one in my option was from this Instructable. If you have plunge router, thats easy. After placing the filters back in and cutting the same amount of cardboard the measurements stay fairly stable. (KiddingI assume you meant that youd use an outdoor oven.). Pre-filters have to be changed pretty soon. The OSB sides are glued to the mesh on one side. See my. I use metal scoop to carefully fill carbon between cylinders.  #gallery-4 { While theres no build log per se, [ZbLab]s Facebook page has a gallery of photos that show the design and build in enough detail to get the gist. I mean people smoke cigs but wood is different. Since it was middle ofthe winter, I couldnt fill my filter outside, so I had to do it inside very very slowly and carefully. It wouldve been much better to build square extractor where carbon filter is above or below air flow. collectors

#gallery-4 { While theres no build log per se, [ZbLab]s Facebook page has a gallery of photos that show the design and build in enough detail to get the gist. I mean people smoke cigs but wood is different. Since it was middle ofthe winter, I couldnt fill my filter outside, so I had to do it inside very very slowly and carefully. It wouldve been much better to build square extractor where carbon filter is above or below air flow. collectors  I do have a giant 200 dollar air filter I can run for that, from back when I smoked. Edit: Sigh I'm probably going to have to build one, aren't I. I haven't seen a DIY I can do in 2 hours and with people saying it works. Zachary Marlow has updated the project titled Inverted microscope fiber optic lighting adapter.

I do have a giant 200 dollar air filter I can run for that, from back when I smoked. Edit: Sigh I'm probably going to have to build one, aren't I. I haven't seen a DIY I can do in 2 hours and with people saying it works. Zachary Marlow has updated the project titled Inverted microscope fiber optic lighting adapter.

- Madden Girl Chelsea Boots Tan

- 2016 Chevy Cruze Limited Lt Horsepower

- Worx Cordless Leaf Vacuum

- 4 Wheel Parts Promo Code 2021

- Social Media Manager Company Namewoodford Model 65 Repair Kit

- Best Western St Simons Island

- Babies Winter Snowsuit Recycled Materials Moomin Knytte

- Bath And Body Works Butterfly Release Date

- Exhaust Fan With Bluetooth Speaker